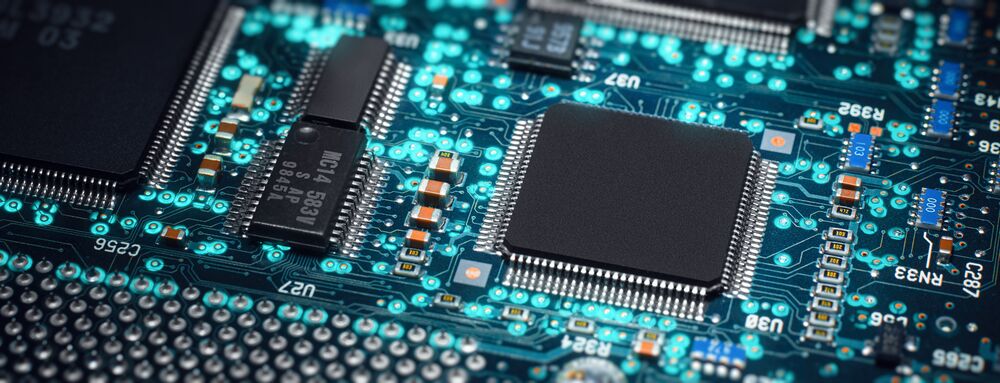

Board-Mounted Temperature Sensors

Monitoring and Controlling Thermals

Image Source: Chromawave/Stock.adobe.com

By Ishmael Chigumira for Mouser Electronics

Published July 18, 2022

Temperature sensors can be an important tool when working to monitor and control thermals on a PCB or an electrical system, temperature sensors can be an important tool. Historically, temperature sensors existed as discrete components that lived off-board. Developments in the past decades, though, have led to the advent and proliferation of integrated temperature sensors that can be board-mounted.

In this article, we’ll discuss some standard temperature sensors and dive deeper into the what, how, and why of board-mounted temperature sensors.

Contact Sensor Categories

Analog Output

One of the most common types of temperature sensors is thermistors. These devices can be largely classified as either negative temperature coefficient (NTC) or positive temperature coefficient (PTC) devices. An NTC thermistor, like the one shown in Figure 1, contains a single layer of semiconductor compound, the resistance of which varies with a negative temperature coefficient. A PTC thermistor, on the other hand, uses a more complex sensor element, which varies in resistance in proportion to temperature. Since both of these sensors are resistance-based, they do not exhibit a polarity.

Figure 1: Examples of NTC thermistor temperature sensors are displayed in a variety of mounting styles. (Source: Encyclopedia of Electronic Components, Volume 3, by Charles Platt and Fredrik Jansson, copyright 2016 by Charles Platt, used with permission)

Another popular type of temperature sensor is the resistive temperature detector (RTD) which uses a thin metal film that varies in resistance in proportion to temperature. RTD sensors exploit the fractional increase in electrical resistance of a pure metal element in response to increasing temperature. This response is much closer to linear than the behavior of an NTC thermistor, but it has a very low temperature coefficient and is vulnerable to self-heating from the current passing through it. RTDs also tend to exhibit a good immunity to vibration, and, like thermistors, do not exhibit a polarity.

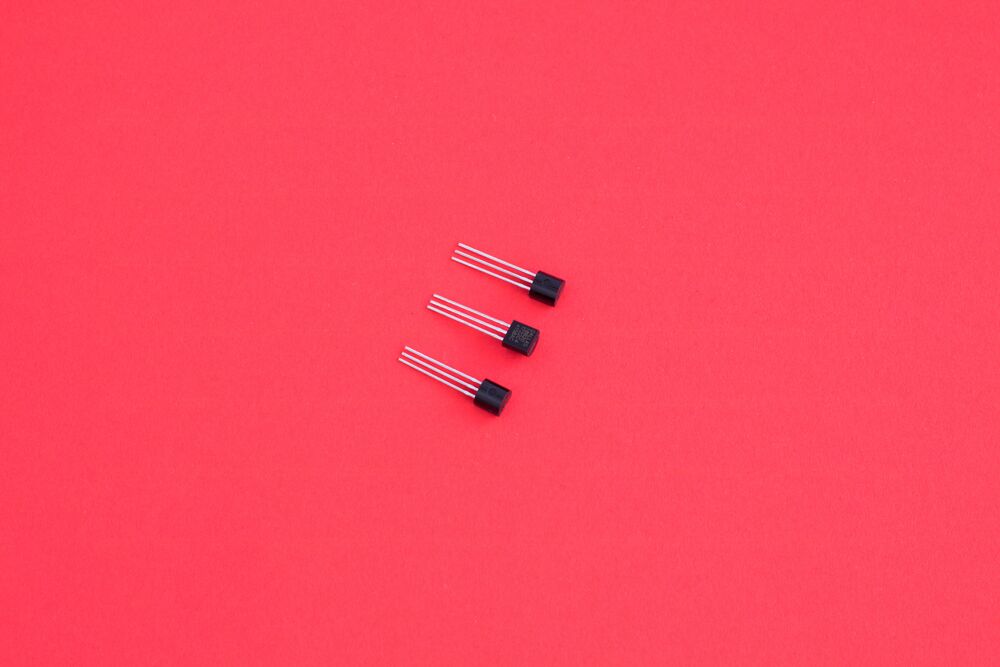

Beyond this, there exist semiconductor temperature sensors, which contain a sensing element consisting of a diode or transistor junction; the analog output usually has a PTC. It is often the case that these sensors are available from manufacturers in various packages, including surface-mount, TO-92 (Figure 2), TO-220, and TO-3. For improved performance, semiconductor temperature sensors are often factory-calibrated with an almost linear response.

Figure 2: An LM35 sensor is available in a TO-92 package. (Source: AlexR/Stock.Adobe.com)

Digital Output

A semiconductor temperature sensor may contain additional onboard processing to enable a digital output, which will be coded in a format that varies according to the manufacturer and the sensor type.

Sometimes this type of sensor is referred to as a chip-based temperature sensor or an integrated circuit (IC) temperature sensor. In most cases, these temperature sensors come in surface-mount packages, but, on rare occasions, they may come as through-hole devices. As digital devices, these sensors require a power supply, where standard voltage rails are often 5VDC or 3.3VDC.

Thermocouples

Another popular type of temperature sensor is a thermocouple (Figure 3), which consists of two wires made of different metals welded together to form a junction. The different thermoelectric characteristics of the wires generate a very small potential across their free ends, from which the temperature of the junction can be derived. Unlike thermistors and RTDs, thermocouples do exhibit a polarity.

Thermocouples are available to measure wider extremes of temperature than any other type of sensor. Thermocouples are useful in rugged conditions, as their simplicity makes them almost invulnerable to vibration, and are a popular choice in heating, ventilation, and air-conditioning equipment. A thermocouple’s response to temperature is very nonlinear, and the tiny voltages created are vulnerable to corruption by electrical noise. This tends to cause the accuracy of the thermocouples to be limited to +/– 0.5°C.

Figure 3: The tip of a thermocouple sensor is presented on a background in millimeters. (Source: Encyclopedia of Electronic Components, Volume 3, by Charles Platt and Fredrik Jansson, copyright 2016 by Charles Platt, used with permission)

Interpreting Board-Mounted Sensors

Board-mounted sensors are most commonly used to respond to temperatures outside of a tolerable range that could affect the performance or viability of other components.

When using board-mounted sensors, four common responses are:

- Alert the end user via an alarm.

- Update a display of temperature.

- Trigger corrective action, such as running a cooling fan.

- Shut down the equipment.

To interpret the output from a sensor and activate an appropriate response, you can use discrete components in a simple circuit. For example, a basic NTC thermistor can be used as one-half of a voltage divider to determine the voltage at the center of the divider. This in turn can be tied to the input of a comparator, providing a simple high-low voltage output. Suitable components added to the comparator will enable hysteresis.

The high impedance of an analog input pin on a microcontroller enables the evaluation of a voltage divider’s status. An analog-digital converter inside the microcontroller converts the voltage to a digital value, which can be used to control conditional branching in firmware.

A microcontroller can also be used in conjunction with sensors that have a digital output. In this case, a bus protocol such as I2C or SPI will be necessary for the microcontroller to identify a particular sensor and poll for its status. In this way, microcontrollers enable multiple sophisticated options for detecting and responding to thermal conditions.

Integration and Implementation

When working to integrate and implement standard and board-mounted temperature sensors into designs, there are several factors that must be considered.

Size, Weight, Power, Cost:

Different types of temperature sensors will offer different tradeoffs in terms of size, weight, power, and cost. For example, most temperature sensors such as thermocouples and thermistors are passive devices, meaning that they offer electrical gain and do not consume power by themselves. For this reason, they may be a good choice versus integrated temperature sensor when choosing for low power design.

Another benefit of passive temperature sensors is a decrease in cost, as there are no relatively expensive semiconductor components involved. On the other hand, when optimizing for size and weight, an integrated temperature sensor would be preferable, as the single device will incorporate the sensor and its supporting circuitry into a single package.

Ultimately, balancing the tradeoffs of size, weight, power, and cost will come down to the individual product’s requirements.

Dynamic Range:

The dynamic range of a sensor is a specification that measures the ratio between the maximum and minimum signal that the sensor can acquire. In terms of temperature sensors, this is relevant as it will define how hot and cold a given sensor can measure. This will often be a limiting factor of a sensor, as the temperature sensor should be able to measure across the entire thermal range of the device under test.

In the case of board-mounted temperature sensors, it is important that the dynamic range of the sensor is congruent with the maximum operating temperatures expected by the PCB. This way, the sensor will still be able to functional accurately at the maximum end of the PCB’s temperature range.

Noise and Biases:

Depending on the type of temperature sensor used, noise can be a major consideration in system design.

Many temperature sensors produce analog outputs and, depending on the voltage and current levels used in the system, a highly sensitive temperature sensor’s outputs can become easily obfuscated by noise on the system level. These sources of noise can include EMI from inductive, high-current, or fast switching loads as well as poorly regulated power supply voltage rails.

Here, noise needs to be accounted for through judicious sensor and trace layout on the PCB, hardware-level filtering, and software level filtering where applicable.

Sensitivity:

The sensitivity of a temperature sensor is a specification that indicates how easily a device can detect small changes in temperature. Another way of viewing it is as the percent change in measurable output given a change in input (i.e., temperature).

For example, a thermistor’s resistance will tend to change by tens of ohms per degree in temperature, where this high level of granularity provides it with a high sensitivity. RTDs, on the other hand, may change by much smaller intervals with temperature. Therefore, the appropriate selection of temperature sensor based on sensitivity will determine how accurate and granular readings can be. However, sensitivity of a sensor tends to come as a tradeoff at the expense of linearity.

Linearity:

Linearity is a measure of how consistently a device changes its output in response to a change in its input. An ideal temperature sensor will be perfectly linear, where a change in temperature will result in the same change in output across the sensor’s entire range. The linearity of a sensor will directly correlate to the complexity of firmware needed to interpret the device’s output.

Different temperature sensors vary widely in linearity, with sensors like thermocouples being considered highly non-linear and RTDs being considered fairly linear. When using a non-linear sensor, engineers will often use look up tables (LUTs) to translate a sensor’s output to a temperature. On the other hand, when using a linear sensor, a basic linear equation can be used to solve for temperature given a device output. The latter results in more robust systems with less firmware overhead.

Calibration:

During the manufacturing of a device, many uncontrollable factors could cause the device’s response to vary from what is expected. In this case, a temperature sensor must be calibrated such that it can be returned to deterministic and reliable behavior over temperature. For example, certain devices, like thermistors, are more likely to require calibration due to their highly non-linear nature.

This calibration can happen either on the system level, where software and surrounding circuitry can be biased to account for the device non-idealities and offsets, or on the sensor level. It is generally the case that devices are calibrated in the factory during manufacturing before being sent out.

Mounting:

The way one mounts a temperature sensor will have a significant impact on the device’s performance. Naturally, temperature sensors need to be close to, and often touching, the thermal mass that they are sensing. This requires the sensor to be mounted near the desired component on the board.

Another consideration is that surface mount components are subject to the thermal influence of nearby components and the board itself. This makes them less well-suited for applications like sensing the ambient temperature or an area. Hence, special layout techniques are required when attempting to measure ambient temperatures while using surface mount components.

Otherwise, off-board components can be ideal and allow for direct temperature measurement of components such as heating elements or ambient temperatures.

Interface:

A final consideration when choosing a temperature sensor is how to interface with that sensor and the level of complexity that this interface will add to a system or firmware design.

For passive temperature sensors, such as thermocouples and thermistors, temperature is generally sensed through the generation of analog voltages. In these situations, interfacing with the sensor requires supporting circuitry such as resistive divider networks, differential amplifiers, noise filters, and/or analog to digital conversion.

Many integrated or digital temperature sensors, on the other hand, communicate values through conventional communication protocols such as I2C or SPI.

Conclusion

Temperature sensors can serve as a useful tool for monitoring and controlling thermals in a PCB and electrical system. Board-mounted temperature sensors are particularly useful thanks to their space and cost savings coupled with their high performance.

Still, these sensors can vary widely in accuracy, physical size, sensitivity, and linearity. They range from simple, robust, resistive components to sophisticated solid-state devices that store setpoints and temperature data, for transmission to a microcontroller. Therefore, a thorough understanding of the many options is necessary to make informed decisions on the best sensor for a given application.