Lighting Applications Found At The End Of The Rainbow

By Paul Golata for Mouser Electronics

LEDs have taken over many illumination applications over the past decade because they offer a number of advantages over traditional lighting solutions:

- Longer lifetimes in the field, which reduces cost and upkeep

- Greater efficiency by allowing more lumens of light per unit of electrical power consumed, known as optical efficacy (lm/W)

- Faster on-off switching without any adverse effects

- Smaller physical size, which broadens the potential uses

- Increased physical robustness to physical shock, vibration, and mechanical stresses

This trend toward using LEDs is something we see in the everyday world around us, whether it is the new light canopy at the gas station or the way food and clothing is lit in retail locations. LEDs illuminate the world around us with white light, which incorporates various spectrums of red, green, and blue colors, and enable us to see things in a new and better way.

LEDs are also bringing about changes that aren’t visible to the naked eye; they are changing the way we work with lighting applications outside the rainbow of colors in the visible spectrum. They are enabling new improvements at the end of the rainbow—beyond blue and beyond red. They are changing applications that are in the ultraviolet and infrared spectrums, light that is beyond the ability of human light-sensitive rod cells and cone cells to detect and respond to.

Ultraviolet: Beyond The Rainbow’s Edge Of Blue

The human eye senses color from about 400nm–700nm. As many people learn at a young age, the rainbow’s colors may be viewed from the perspective of six major color components: Red, Orange, Yellow, Green, Blue, and Violet (Purple). Wavelengths that impinge upon the eye at between 430nm–495nm are perceived as blue. Lower wavelengths than 430nm are perceived as violet (purple). At some point around 400nm, the eye can no longer see the violet color and can no longer distinguish it (Figure 1).

Blue 430nm-495nm

UV-A/Violet 360nm-430nm

Figure 1: Wavelengths of light for Blue and Violet (Source: Mouser Electronics)

The spectrum of light below violet is called Ultraviolet (UV), which covers three distinct ranges:

- UV-A (Long-Wave): 315nm–400nm

- UV-B (Middle-Wave): 280nm–315nm

- UV-C (Short-Wave): 100nm–280nm

The shorter wavelength uses of UV light are primarily related to sterilization and germicidal applications. In these (higher frequency) of light means that the photon has more energy than longer wavelength (lower frequency) light, such as in the visible spectrum (400nm–700nm). This high energy is used to destroy harmful biological agents for applications involving purification of air, water, medical related equipment, and the like. At this time, it is difficult for LEDs to be produced at these very short wavelengths due to the bandgap levels of the semiconductor materials involved. This means that UV-B and UV-C applications have limited UV LEDs in use.

UV LEDs have made their greatest impact within the industry in UV-A applications (315nm–400nm). This is due to the reality that various key semiconductor manufacturers have been more successful in producing semiconductor materials and products that can emit light in this range. Three primary areas of application for UV-A LEDs include UV-curing, inkjet printing, and scientific instrumentation. Let’s look further at how UV-A LEDs have made inroads into industrial inkjet printing.

Inkjet printing is a method reproducing digital images on various substrates like paper and plastic. Conventional inks are either oil- or solvent-based, and dry via oxidation or evaporation, respectively. Heat from an infrared light accelerates these drying processes, but can lead to substrate shrinkage and warping. To avoid this, inkjet manufacturers developed UV-A curing inks that stabilize by photochemical crosslinking, meaning that polymerization happens when a binding agent, pigment, and photoinitiator (UV-A light) are brought together. The energy from the UV-A light creates free radicals that look to combine with other elements, which make a strong linkage between the binding agent and the pigment. The advantage to this process is that when fully cured, the substrate material has not been exposed to heat, so its surface remains smooth and uniform. Additionally, UV-A curing is more environmentally friendly because the UV-cured ink retains 100 percent of the ink in the dry coating and because there is no evaporation or oxidation losses of material to the environment, thereby reducing pollution and increasing its eco-friendliness.

For many years, UV light has been introduced through a UV mercury vapor lamp. These lamps maximize the speed of the inkjet process due to their wide, multi-spectral UV wavelength output, which more fully maximizes the reactive components of the ink. UV-A LEDs are inherently monochromatic, and as such, provide more limited engagement for UV curing to happen. However, all of the aforementioned LED advantages still apply. Manufacturers are continuing to improve inks to work with the latest UV-A LEDs, which results in inkjet printing that’s best suited for lower productivity equipment rather than high productivity and high performance systems. Having made many inroads to date, as higher power UV-A LEDs continue to be developed, their reach will continue further into this industry.

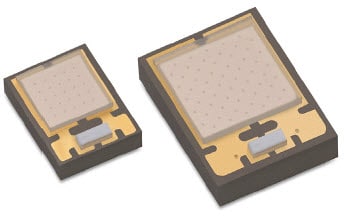

Many LED companies are working to expand their offerings in UV-A LEDs including Lumileds, Led Engin, Luminus Devices, Everlight Electronics, and Wurth Electronics. For example, Lumileds LUXEON UV U Line LEDs are high-power, density-efficient devices (Figure 2). Designed to be very small to fit in places that previous UV LEDs could not access, they are un-domed (without optics) surface-mount devices that can be assembled into tight arrays with spacing of only 0.2mm. Their small die sizes allow for precise optical control. They are available in ultraviolet (380nm–400nm) and violet (400nm–420nm) wavelengths to address different applications, including curing, medical applications, analytical instrumentation, and UV photoreaction.

Figure 2: Lumileds LUXEON UV U Line LEDs (Source: Lumileds)

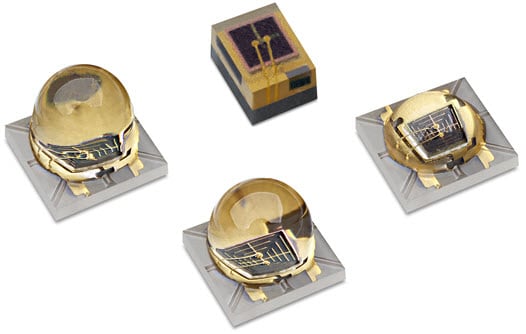

Focusing on high-power UV LEDs, LED Engin has recently designed three specific series of small, ultra-bright UV LED components in the 385nm–410nm wavelength range to address ink and adhesive curing, dental curing and teeth whitening, counterfeit document identification, equipment sterilization, and medical applications. The LZ4 series is built upon a 7mm x 7mm (49mm2) substrate, the LZC series upon a 9mm x 9mm (81mm2) substrate, and the LZP series upon a 12mm x 12mm (144mm2) substrate, with increasing package size allowing more die to be placed into the assembly (Figure 3).

Figure 3: LED Engin LZP00UB00 Series LED Emitters

Infrared: Beyond The Rainbow’s Edge Of Red

But every rainbow always has two ends. Just as ultraviolet resides below blue on the lower wavelength spectrum of the rainbow, on the high side, above red, resides another spectrum: Infrared (IR). Like UV LED light applications, IR is also experiencing rapid growth due to the inherent advantages that LEDs bring to these applications. Let’s look at some of the ways IR LEDs are making an impact.

Let’s start by understanding where this end of the visible rainbow is. We perceive wavelengths between 610nm–740nm as red, though wavelengths above 700nm are very hard for the human eye to see. Accordingly, there is some overlap when discussing the boundary of where red stops and IR starts. It is generally taken as being somewhere in the range of 700nm–740nm, depending upon conditions (Figure 4).

Red 610nm-740nm

Near Infrared 700nm-1500nm

Figure 4: Wavelengths of light for Red and Infrared (Source: Mouser Electronics)

Whereas UV is comprised of three sub-divisions, IR light is comprised of five:

- Near-IR (NIR): 700nm (0.7µ)–1500nm (1.5µ)

- Short-IR (SWIR): 1.5µ–3µ

- Middle-IR (MWIR): 3µ–1,000µ

- Long-IR (LWIR): 8µ–15µ

- Far-IR (FIR): 15µ–1,000µ

Each distinct wavelength range finds some use in industrial and commercial applications. For our purposes we will only be discussing NIR LEDs, which are particularly well suited for situations calling for something to be illuminated that is not visible to the human eye and that may be easily sensed electronically. The reason why they work well for these applications is that many electronic sensors, such as silicon detectors, are available that have optimal responsivity curves in the NIR spectrum by the underlying physics behind their design.

For example, NIR LEDs are excellent for applications involving illumination for cameras used in surveillance security systems and CCTV, as well as in machine vision. They are used on highways to gather toll tag and license plate information. They are employed in designs requiring biometrics for access control and identification. Their ability to be used with silicon photodetectors makes them practical for touchscreens, gesture recognition systems, and smoke detectors. If you have ever seen CBS's hit TV show CSI: Crime Scene Investigation, then you are familiar with how many clues are evaluated by using spectroscopy, including NIR spectroscopy. One exciting new way NIR spectroscopy is being used is for ascertaining the quality and characteristics of items that we ingest into our bodies, including foods and medicines.

Similar to how humans see objects based upon reflected visible light, NIR spectroscopy employs NIR LEDs as an illumination source and shines it on a material placed under examination. The material absorbs and reflects light based upon its inherent physical characteristics, its molecular makeup. A wavelength selective detector is arranged to view the reflected light, which provides information specific to the object under examination. The system and user are then able to determine what types of materials are present based upon comparison with known entities.

In the past, large, complicated spectroscopy machines were required, but with the development of smaller, more powerful NIR LEDs, handheld and portable devices are becoming more commohandheld and portable devices are becoming more common.

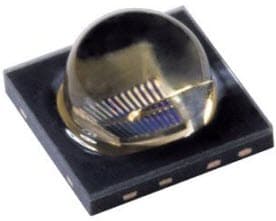

To this end, suppliers including Lumileds and Osram Opto Semiconductors have developed products such as their respective Lumileds LUXEON IR LEDs (Figure 5) and IR OSLON® Black Series LEDs (Figure 6).

Figure 5: Lumileds LUXEON IR LEDs

Figure 6: Osram Opto Semiconductors IR OSLON® Black Series LEDs (Source: Osram Opto Semiconductors)

One of the secrets to how companies like Osram Opto Semiconductors produce higher power NIR LEDs is through phosphor conversion. The LEDs themselves may put out most of their optical energy in the visible wavelength spectrum, such as in the blue spectrum. When this visible light contacts the phosphor deposited on the top side of the LED, it produces luminescence, which shifts the wavelength of light higher. Through careful design and process control, a variety of NIR wavelengths can be produced at nominal wavelengths, including 850nm and 940nm. Optical domes provide further options for controlling where and how the light is emitted. NIR spectroscopy bandwidth and performance can be improved by using more than one wavelength in the system design.

Conclusion

LEDs are making life better. Their inherent advantages allow designers to develop a host of new products that meet people’s needs. UV light includes three distinct wavelength sub-divisions beyond blue, with one—UV-A—helping LEDs provide solutions for curing, inkjet printing, and disinfecting scientific instrumentation. On the other end of the spectrum, IR light covers five distinct wavelengths and has advanced applications in NIR spectroscopy.

While the transition from incandescent lighting sources to white-light LEDs has revolutionized the illumination world, lighting applications for white-light LEDs are advancing even faster. These lighting applications are found outside the end of the rainbow—at its edges—where both UV and NIR applications are incorporating LEDs into their designs. Even though the light used is not visible to the naked eye, it helps us see beyond the rainbow.