Digital Twins

Bridge Product Design and Manufacturing

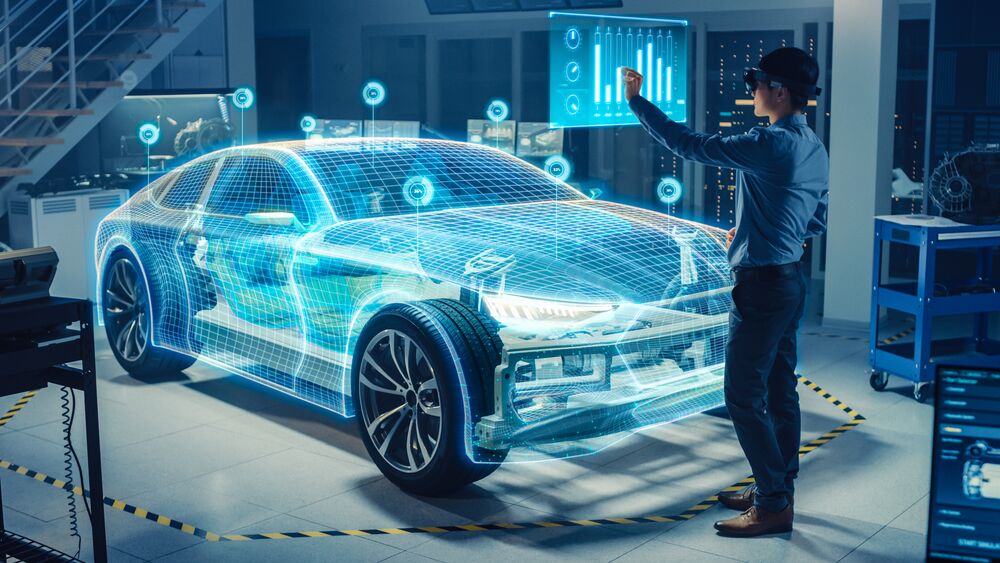

Image Source: Gorodenkoff/Stock.adobe.com

By Dr. Michael Grieves for Mouser Electronics

Published January 30, 2023

The underlying premise in product manufacturing is that tasks are broken into two categories: (1) The most efficient use of physical resources and (2) physical resource waste. Lean manufacturing has enabled manufacturers to reduce time within the production system as well as response times from suppliers and customers. Industry 4.0 has enhanced efficiencies by shortening the time between discovering and fixing problems in real time. These and related advances have improved efficiencies, but ever-increasing demands for speed, quality, low cost, and customization are driving manufacturers to find new ways to meet these needs.

Design manufacturability is the general engineering practice of designing products so that they are efficient to manufacture. The use of digital twins (DTs) is emerging as a solution that bridges the gap between design and manufacturing, with long-term potential to maximize efficiency and minimize wase.

Gaps between Design and Manufacturing

Even today, with advanced engineering and manufacturing capabilities, it is common for products to be well designed but ultimately not manufacturable. For example, a design may specify a 2-cm wall between compartments to meet harsh environmental requirements, but the manufacturer may not be able to manufacture this thickness or work with the alloy the design specifies. Similarly, a design may specify a single bar with a groove in it to be made using subtractive manufacturing, but the manufacturer can create the groove only by using a single bar with two other bars welded on top of the first. The potential manufacturability issues are limitless.

Part of the problem is that design engineering and manufacturing have become siloed phases of the product life cycle, each with its own requirements and information. Rather than manufacturability being part of engineering design, the teams and processes are separate and sequential, with designers not getting a full view of the manufacturing capabilities, limitations, and requirements they need.

Manufacturing design guidelines help bridge this gap, but they are not a panacea. As with other areas of the product life cycle, guidelines and best practices continue to evolve to meet rapidly-changing customer demands. Similarly, transparency into existing components and products used in design may not be available or may be outdated.

Product modeling and simulation tools have advanced design engineering considerably, but they are limited in terms of design manufacturability, too. Simulations replicate products in their current state, which limits designers’ ability to test different configurations, components, and materials without building additional models. Even aggregated simulation data are rooted in testing history, and simulation results may not be accurate because human input and assumptions are part of the simulation equation.

As a result, product designs may meet functional requirements but ultimately not be manufacturable—or at least manufacturable in a way that meets cost or delivery demands. And so, an extended back-and-forth between designers and manufacturers ensues to address manufacturability issues, wasting considerable resources even before production begins.

Digital Twins: The Bridge to Manufacturability

Over the past several years, the use of Digital Twins (DTs) has increased across a broad swath of industries, including aerospace, automotive, ship building, oil rigs, and medical devices. The idea of a DT is to be able to design, test, manufacture, and support products using virtual reality before any work is done in the physical environment.

DTs are the digital counterparts of physical objects and processes in real-time. The digital twin is a computer program that simulates how a product or process will perform based on real-world data. Data scientists, engineers, and IT professionals can run cost-effective simulations to optimize a physical asset's state, predict its response to changes, or improve operations. Additionally, DTs can be used to identify potential flaws early in the design phase of an object or process. Artificial Intelligence, the Internet of Things, Industry 4.0, Big Data, and software analytics can all be utilized to enhance the output of DTs. Product drawings and engineering specifications have evolved from handmade drawings to computer-assisted designs to model-based systems, and now to DTs.

Among many efficiency gains that span the entire product life cycle, DTs can bridge the divide between design and manufacturing like no other solution or combination of solutions can. A DT prototype (DTP) is akin to a product recipe that includes all the design pieces that would go into a complete product but in digital form, including the product’s physical attributes, properties, physics, computational flow, operating parameters, test procedures, bill of materials, and manufacturing bill of process.

The DTP is the most realistic representation of in-development products, and it can be handled and manipulated at various levels of granularity—at the part, product, or whole-system level. The result is a level of detail about manufacturability that enables designers to account for the many interdependencies between the two functional areas. What’s more, a DTP’s algorithmic engine can extrapolate how changes in design, materials, and components affect manufacturability, eliminating the need for multiple physical prototypes.

DTs can also model manufacturing processes and help guide design decisions that have manufacturing implications. For instance, DTs can determine whether additive or subtractive processes would be better from cost, functionality, and durability standpoints. They can further represent the variety of processes used to manufacture complete products—injection molding, broaching, turning, machining, or any number of others. For additive manufacturing to become a dominant manufacturing process, DTs are a core requirement.

Finally, DTs not only bridge today’s design-manufacturing gaps: They are also the bridge to future needs. For instance, today’s customers are demanding product options and personalization as part of core product offerings, which pose additional manufacturing headaches in terms of manufacturing setup, materials inventory, time to market, and more. There are no limits to how many DTs can be produced during initial or subsequent design processes. Further, information gained throughout a product’s life cycle can be used to determine future customized and personalized products—and their manufacturability.

A Look Ahead

Gaps between engineering design and product manufacturing can result in significant waste even before manufacturing begins. DTPs have enormous potential to close these gaps and optimize designs for manufacturing and beyond. Creating DTs is not inexpensive, but the cost of information is still far lower than the cost of creating multiple physical prototypes or manufacturing by trial and error. In the quest to meet increasing demands for good, fast, cheap, and customized products, using DTs across the entire product life cycle will be the only way to meet tomorrow’s manufacturing demands.