Smart Linear Actuators Making the Move in Consumer Products

Image Source: Who is Danny/Shutterstock.com

By Bill Schweber for Mouser Electronics

Published September 23, 2021

Introduction

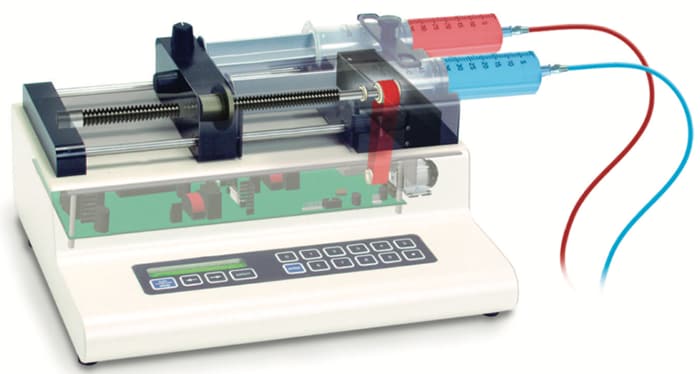

Linear actuators transform the inherent rotation of a motor rotary into a straight-line motion for small and large loads and are often unseen by the user. They are comprised of a motor, linear guides, drive-control electronics. There may also be provisions for wired/wireless connectivity and controI. Linear actuators are standard components widely used in automotive, aerospace, agriculture, manufacturing, solar, medical, and robotics (Figure 1). They are increasingly making their way into the home and consumer products in visible and less visible household functions. In doing so, these actuators are easing some otherwise complex tasks while also enabling new interior-design options.

Figure 1: Smart linear actuators provide precise motion control, such as in this programmable processor-controlled syringe for metered infusion of medications (Image source: Helix Linear: Wikipedia)

Power can come directly from the AC line or a small AC/DC converter, depending on the applications. The actuator extends and retracts to position the load, which may involve lifting or lowering an object or opening/closing a cover. Among the applications in consumer settings are window blinds and curtains, retractable awnings (Figure 2), TV lifts (Figure 3), recliners, adjustable beds, skylights, retractable countertop kitchen-vent hoods, and HVAC airflow dampers.

Figure 2: Extending and retracting an outdoor awning is a good application for the linear actuator. (Image source: Studio Harmony/Shutterstock)

Figure 3: Linear actuators make it easy to raise a flat-screen TV from its cabinet and lower it as well. (Image source: Häfele America Co)

Historically, hydraulic or pneumatic pistons and linear actuators have been relatively rare in the home and consumer environment, while they are used extensively in industrial settings employing motion. The reasons are cost, size, complexity of control, need for maintenance issues such as seal replacement, and practical concerns with using compressed air or hydraulic fluid in a piston in a home setting.

All of that has changed due to advances in small, powerful electric motors, high-performance control electronics that manage the motor and the actuator, as well as the ability to easily add a wired or wireless interface for remote control via an infrared control similar to a TV control, Bluetooth connection, Wi-Fi link, or proprietary wireless link. The availability of ubiquitous AC outlets in the house further simplifies since meeting the demands of the smart linear actuator for the low-duty cycle/higher peak power is no longer a concern, and battery-less operation means one less thing with which the homeowner must be concerned.

Multiple factors driving linear actuator designs-ins

As usual, with advances in technology and broader adoption, the increase in smart linear actuators is due to multiple factors bolstering each other rather than a single, overriding reason. These actuators are merging user needs and expectations with easier-to-use yet small and powerful electric motors, plus low-cost, versatile connectivity and communication interfaces. As is often the case, user applications are driving demand, while that same demand drives the new technologies that enable those applications in a complementary, reinforcing cycle.

Among the factors are:

- Smarter homes: The increase in smart homes with the preference for home automation, smarter home “accessories,” and home networks.

- Population and demographics: An aging population that wants to remain in their homes but needs motor assistance for some tasks; and a younger population comfortable with—and even expecting—ubiquitous automation and high-tech functionality.

- Electric motors: Availability of reliable, quiet, powerful, and controllable electric motors—DC brushed, DC permanent magnet brushless, DC stepper, or AC—rather than messy hydraulic or pneumatic actuators and their compressors and hoses; also, there is no start-up lag while compressor pressure builds up.

- Ease of motor control: These smaller yet powerful electric motors are easier to control, and work with sufficient precision, eliminating the need for hydraulic or pneumatic piston arrangements and control-valve arrangements (see sidebar, “Alternatives to electric motors”); the motor controller can include motion-trajectory profiles with soft starts and stops, and link and even synchronize multiple actuators.

- Capabilities: More user-focused features such as timed operation and self-diagnostics are embedded in smaller, lower-cost controller assemblies.

- Remote control: The ability to incorporate inexpensive, remote control via networked and non-networked connectivity, using infrared, wired, and wireless links.

- Mechanical improvement: The linkage which converts the motor’s rotary output into linear motion now can be smaller, lighter, quieter, and maintenance-free through improved materials such as leads, screws, and nuts, or pulleys and belts, made of engineered plastics.

- Efficiency: Today's motors, controllers, and communications interfaces run cool, are small, easily installed, and require only a small, convenient line-powered supply.

Inside a smart electric linear actuator

A smart linear actuator powered by an electric motor is a relatively simple electromechanical device capable of precisely controlled motion. It is often invisible in mass-market applications such as a DVD drive or the print-head carriage of an inkjet printer.

At its heart is a motor that provides a rotary-motion output via a shaft. The function of the mechanism attached to the shaft is to transform this rotary motion into a controlled, repeatable, and—for most consumer-home applications—reasonably but not highly accurate linear position.

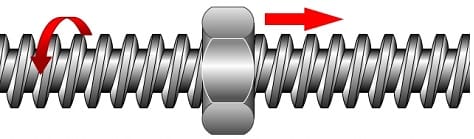

There are several ways to accomplish this transformation. One economical and effective way is to connect a long lead screw to the motor shaft with a nut riding on the lead screw (a rod-like threaded carrier) (Figure 4). The load to be moved is attached to the nut, which moves along the lead screw as the shaft and thus leads screw turns.

Figure 4: The principle of using a lead screw for linear actuation is a simple adaption of the threaded lead screw and nut, with the motor turning the screw and, by doing so, moving the nut and load it carries. (Image source: Design and Technology Resources)

For cases where the load is heavy and lower friction is required, the simple lead screw is replaced by a contoured thread on the rod, and the simple nut is replaced by a rotating assembly of ball bearings in a housing. Both the lead screw and ball screw approaches use the same underlying concept of a moving element riding the longer threaded rod and carrying the load.

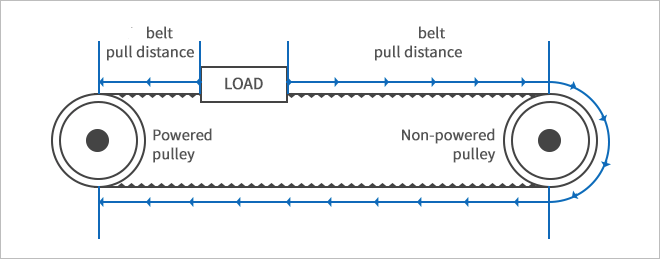

A lower-cost alternative to using a screw on the shaft is to put a toothed pulley, often made of plastic, on the shaft and have that engage a flexible, non-stretching drive belt with matching teeth (Figure 5). The far end of the belt rides on a separate unpowered idler pulley which maintains proper loop tension while the load rides on the belt. This pulley and belt approach is perfect for longer-travel linear applications such as pulling a curtain across a window.

Figure 5: In some cases, a toothed belt and matching pulley translate rotary motion into linear motion. (Image source: Teknic, Inc.)

Smart motor control: the key to simplicity

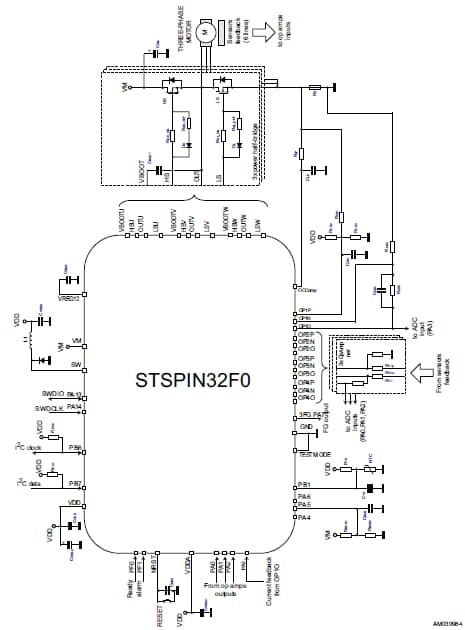

In addition to a the motor and its attached mechanical assembly, a linear actuator’s motor needs a controller, also called a motor driver. This electronic unit not only controls the flow of current to the motor windings, but it also has the "smarts" to determine what power control actions and sequences are needed to direct the motor and thus the load to the intended location. These smart controllers have become increasingly sophisticated and require very little direct oversight by the system designer. For smaller motors of many consumer applications needing up to around 1 to 2A drive current, the motor-driver MOSFETS may be integrated into the controller IC. They can also include an SPI, I2C, or UART interface for connecting to other components in the system, such as the infrared, wired, or RF wireless interface components.

One example is the STSPIN32F0 Advanced BLDC Controllers brushless DC motor controller with an embedded microcontroller unit (MCU) from STMicroelectronics (Figure 6). This advanced IC combines basic power management, an ARM processor core, memory, analog inputs for sensors, drivers for the motor MOSFETs, a selection of serial interfaces, and much more. Users can develop their motion-control algorithms to match the application or start with "canned" packages and customized as needed.

Figure 6: A device such as the STSPIN32F0 advanced brushless DC motor controller from STMicroelectronics incorporates many management and I/O features for motor control. (Image source: STMicroelectronics)

The system microcontroller does not have to provide specific step-by-step details of the desired linear-motion action and associated motor sequencing with these motor controllers. Instead, the system microcontroller can be a low-end unit and has to issue a command to "move the load to position x at rate y." The smart controller makes it happen; in many cases, the microcontroller is integrated into the motor controller IC. The controller also provides various forms of protection for unexpected occurrences, such as cutting driver power if it detects overcurrent due to the motor stalling when the load is blocked. These are essential but invisible features that make mass-market consumer products more acceptable since they minimize potential sources of electronics failure due to a likely real-world occurrence.

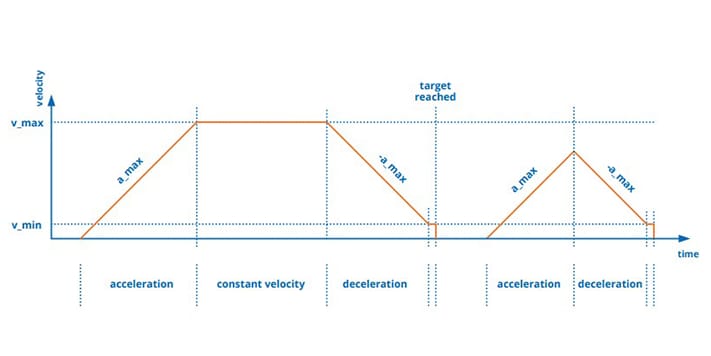

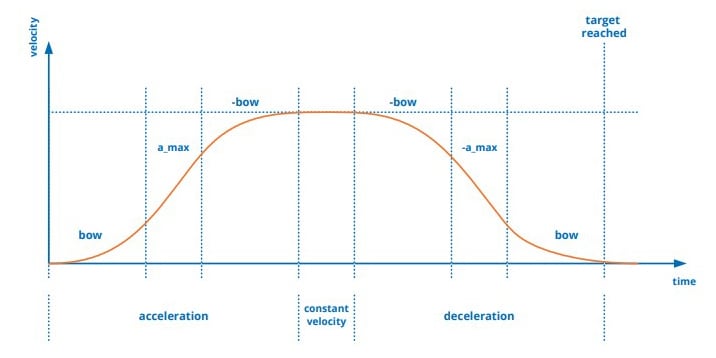

The controller, as illustrated by various units from Trinamic Motion Control (acquired by Analog Devices in August 2021), can implement different motion-trajectory profiles beginning with the basic trapezoidal profile (Figure 7) but also more advanced profiles such as the S-curve (Figure 8). The S-curve has a smooth start and stop in velocity and/or acceleration versus position. As a result, the S-curve profile is less stressful for a load such as a curtain rod or TV lift than the basic trapezoidal profile, and it is also much less unsettling to the consumer.

Figure 7: The trapezoidal velocity profile is the easiest to implement and commonly used (Image source: Trinamic GMBH)

Figure 8: A smart motion controller can provide the S-curve velocity profile; it reduces possible harmful sudden starts and stops, enhances long-term reliability, and is more pleasing to average consumers. (Image source: Trinamic GMBH)

What about feedback?

For applications where more accurate intermediate positioning and confidence are needed, feedback and closed-loop control of the motor are employed. Depending on the application, the feedback sensor is located at the motor or the load. Since the motor connects tightly to the lead or ball screw, it is usually adequate to place the sensor on the motor shaft itself rather than at the moving load; this is mechanically easier to do and eliminates the need to run wires along the track. If the belt slips, there may be concerns for the toothed pulley and belt actuator, so one may need to place the sensor at the load. However, it is usually not required with a correctly-specified and -designed actuator arrangement.

If feedback is needed, the sensor options include Hall-effect devices, resolver encoders, optical encoder, and simple potentiometer encoders. Hall-effect devices have the lowest resolution but are the least expensive and easiest to incorporate into the mechanical design. They are more than adequate except for the highest accuracy situations (generally not the case for consumer products). Resolvers and optical encoders are costly and the hardest to integrate. Potentiometers are low cost but have long-term wear-out and environmental-based reliability issues; but these may not be problems, as the usage rate in consumer products is low, while the physical setting is generally relatively benign.

Sidebar: Alternatives to electric motors

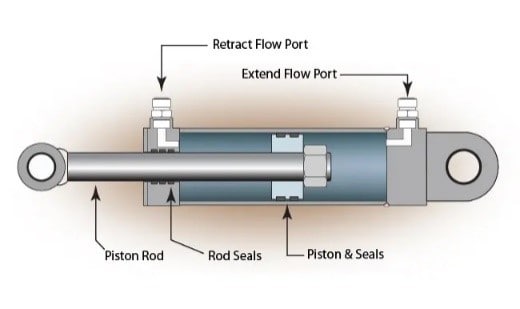

Pneumatic and hydraulic pistons in cylinders have been driving linear actuators for well over a hundred years (Figure 9). They are mature technologies that work well, provide a wide range of capabilities (force, size, speed, accuracy) and other attributes.

Figure 9: The sliding piston in a cylinder and driven by pneumatic or hydraulic pressure has been used in commercial and industrial applications since the start of the Industrial Revolution. Still, it has drawbacks that make it a problematic choice for consumer and home applications. (Image source: Control Products, Inc.)

However, they are generally not a good fit for consumer applications, especially when compared to the realities of today’s electric motors. The reason is that electric motors are easy to install and control and only require a basic electric-power connection rather than an air or oil compressor (which needs electric power for its own motor, of course) and interconnecting piping. Further, unlike hydraulic pistons and their internal oil, which can leak, electric motors won’t make a mess and create a possible environmental hazard if they fail.

Conclusion

Smart linear actuators powered by efficient electric motors enable straight-line electromechanical devices in home-based consumer applications. By combining advances in motion controllers, motors, mechanical-drive components, and wired/wireless connectivity, they offer designers easy-to-use and cost-effective ways to address both existing applications and new ones.