Adding 48V to 12V Means Major Benefits

Adding 48V to 12V Means Major Benefits

Image Source: Sergii Chernov/Shutterstock.com

By Bill Schweber for Mouser Electronics

Edited June 18, 2021 (Originally Published October 15, 2018

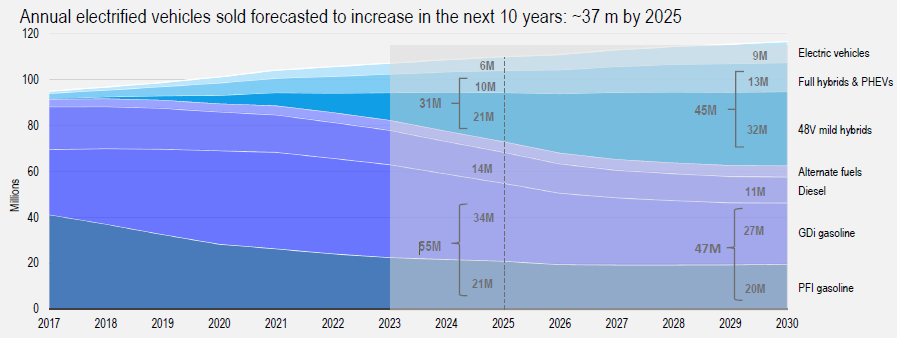

Hybrid electric vehicle (HEV) and all-electric vehicle (EV) designs are highly visible these days. But a less-apparent yet significant trend is impacting the automotive industry: The addition of the 48V direct current (DC) bus to powertrains. This inclusion of 48V is not just for EVs and HEVs. It is also being put in place for more common internal combustion cars, even as the EV and HEV share of the market grows (Figure 1).

Figure 1: The market for electrified vehicles—both EVs and HEVs—is expected to grow rapidly in the next few years, and the use of 48V will be part of the growth story. (Source: Delphi Technologies)

Engineers and car mechanics who were brought up on the ubiquitous 12V battery and components for cars (a standard that is over 100 years old) do not need to worry, because the 12V system is not going away soon. However, in the foreseeable future, 12V will likely coexist with the newer 48V system.

So what's unique about the 48V system? The answer comes back—as it usually does in power situations—to Ohm's law and basic physics related to voltage drop (V = IR), power (P = IV), and power loss (P = I2R). Delivering power requires a combination of current and voltage, although voltage drop (loss) increases linearly with a current and losses increase in the square of the current. In short: Delivering more power at a given voltage takes more current, and more current leads to higher voltage drop and unrecoverable power losses.

This is not a new development, as it was also known by the earliest electrical-energy pioneers. That's why they migrated to ever-higher voltages as they sought to power street lights, homes, and industry. But for cars, the 12.6V (nominal) voltage available from rechargeable, lead-acid batteries was a good compromise with consideration to size, energy capacity (ampere hours), cost, longevity, safety, and other factors.

Today's cars, however, need much more power than those of even just a few cars ago. In addition to basic functions such as a starter, lights, radio, power windows, electrically assisted power steering, networks, and infotainment, many other safety and convenience features are often grouped under the Advanced Driver Assistance Systems (ADAS) heading. ADAS requirements have led to the need for a battery that can deliver more power and more amps at 12V to power the various core functions and these newer peripherals. However, keeping IR drop and I2R power losses at an acceptable level at 12V requires thicker cables, more copper, and larger connectors, which means more costs, weight, and crowding in an already tightly constrained vehicle.

Is 48 the New 12?

After much analysis, the industry decided to use 48V as the other higher voltage. Unlike the lead-acid chemistry of the traditional 12V battery, this 48V battery is lithium-based for higher energy density by weight and volume. The resulting topology is known in the insets as a mild hybrid (Figure 2).

Figure 2: The 12V/48V mild hybrid is a compromise in some ways, but unlike many compromises, this is one that offers many immediate advantages and favorable cost, benefit, and return ratios. (Source: Delphi Technologies)

In this approach, the 48V battery—following guidelines of the proposed automotive standard LV148—serves as a supplement (and combines) with the 12V lead-acid battery, which has a 3kW power rating (Figure 3). Both the 12V battery and the 48V battery will be used along with their distribution cables, and each battery will serve the load when that particular battery is the most appropriate fit for the need. For example, the 12V bus will provide power to the ignition, lighting, and infotainment while the 48V bus will be responsible for the chassis-control systems, air conditioning, active/adjustable suspension, storing regenerative-braking energy, and driving electric superchargers and turbos.

Figure 3: The dual-voltage mild hybrid will allocate the voltage rail and available power to the functions where it makes the most sense from efficiency and operating perspectives. (Source: Delphi Technologies)

Consider one basic component—the engine starter—and how the availability of 48V changes the engine starter’s basic architecture for a better implementation of the start-stop enhancement used to reduce fuel consumption at lights and stop signs and to more easily reach fuel-efficiency goals. In most 12V-only vehicles, the battery powers the starter and the alternator serves as its recharger. However, the combined 48V and 12V batteries allow delivery of up to 10kW, and the starter motor and separate alternator are replaced by an integrated starter-generator (ISG) or a belt start-generator, a 48V lithium-ion (Li-ion) battery (possibly located in the trunk), and a bidirectional DC/DC converter (also in the trunk). The result is a mild hybrid powertrain that works in parallel with the combustion engine. Proponents claim it can provide two-thirds the benefit of a full hybrid but at only one-third the cost, while economy increases it by 15 percent to 20 percent.

The selection of a 48V battery raises two questions: Why not go instead from 12V to 24V? Why just limit the increase to 48V when higher voltages would offer even greater benefits? These questions have very different answers.

About a decade ago, discussion started getting serious about going to 24V, and some key vendors even started production of 24V connectors, switches, relays, and other basic parts. But the net gain of going to 24V was not sufficient for the design disruption that it caused. Further, debate about whether the cars should eliminate the 12V battery completely and just go all in with 24V or have them coexist went unresolved. This dispute slowed the adoption.

As for going above 48V, user safety issues have arisen. In most regions, DC voltages above 60V are considered potentially unsafe and require special wiring precautions, safety interlocks, use of conduits, and physical shielding. Although a 48V system can spike to just under 60V, it is considered safe, thus avoiding the entire issue. Note that for EVs and HEVs, voltages associated with the main batteries are well above 60V, meaning all the safety rules and precautions do come into the design. 48V was as high as conventional and mild-hybrid systems could go to avoid additional safety-related design issues.

What It Takes

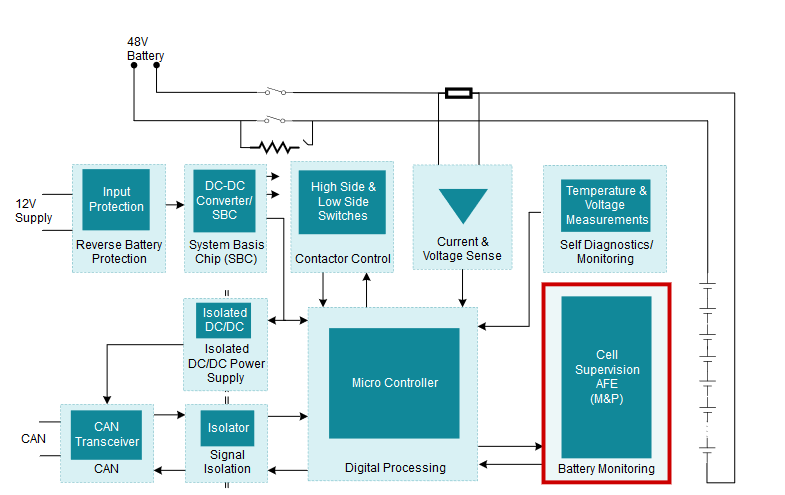

48V use takes more than a new battery structure. In addition to thinner cables and correspondingly smaller connectors, it requires new guidelines on the allowable bend radius (thinner cables allow for tighter bends and eases cable-run issues), consideration of cable insulation, and other mechanical changes. These are the obvious, beneficial, and easy-to-grasp changes. However, because the 12V and 48V buses are not isolated from each other, new functional blocks are necessary to co-manage them (Figure 4).

Figure 4: The relationship between the two buses is complicated and needs careful analysis of the implications of their coexistence. (Source: Texas Instruments)

Other, less-obvious changes exist as well. Circuit-protection components tailored for spikes of up to 30V and 40V on the 12V line require higher voltage ratings to work alongside the 48V, as a lower-rated voltage component would trip in the 48V world. Even basic fuses—which are inherently current-sensitive devices—also have a maximum rating for the voltage across their terminals, so they need to be physically and electrically sized for lower currents (an easy task) but higher voltages (slightly more difficult).

Similarly, the standard component that protects against a reverse-battery connection and is essential at each subcircuit also needs to be scaled to handle the reversal of higher voltage ratings. This is important in case of an accidental misconnection of the primary cables.

However, the real challenge begins with battery management. In most systems, this involves the measurement and management of multiple batteries with the same nominal voltage, but two very different voltages are in the 12V/48V design. The preferred situation from an overall power-management perspective is to allow the 48V and 12V batteries to share and exchange energy when it makes sense.

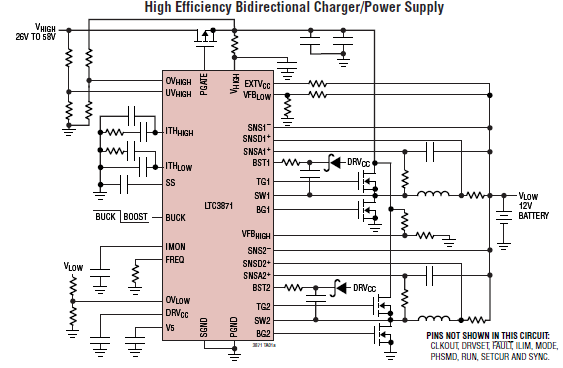

Integrated circuits (ICs) such as the LTC3871 from Analog Devices are designed for this situation (Figure 5). This bidirectional, buck/boost switching regulator (controller) allows both batteries to supply energy to the load simultaneously by converting energy from one battery to the other. It regulates switches in buck mode from VHIGH-to-VLOW and boost mode from VLOW-to-VHIGH depending on a processor-sourced control signal. At the same time, its accurate current-programming loop regulates the maximum current that can be delivered in either direction.

Figure 5: The LTC3871 from Analog Devices is a bidirectional, buck/boost switching regulator (controller) that allows both batteries to supply energy to the load when necessary. (Source: Analog Devices)

The 48V battery itself is special. In principle, its construct could consist of a simple, series connection of four 12V, lead-acid batteries, but this would take up too much space and require heavy-gauge inter-battery cables. Instead, the 48V battery is a Li-ion unit specially designed to deliver that voltage, yet with a volume roughly the same as the 12V battery.

Bosch offers a battery design for automotive 48V systems (Figure 6). It measures only 309mm x 175mm x 90mm, so it can be placed under a car seat or in the trunk. It is a passively cooled component that doesn't need a fan—which would result in a higher cost and lower reliability—and makes no noise. The 7kg unit can deliver up to 13kW of power as it returns the energy it has accumulated.

Figure 6: One available 48V battery is this Li-ion unit from Bosch, which can fit under a car seat, yet needs no active cooling. (Source: Robert Bosch GmbH)

Conclusion

The 12V battery has served the automotive industry well, as its long and successful track record clearly demonstrates. This single, lower-voltage bus can no longer meet the rapidly increasing power needs of today's vehicles because of its IR loss, power dissipation, and other issues.

The solution uses a 48V supplemental battery, which is no longer a coming-soon prediction. The battery is already in use in a large number of car propulsion sources, ranging from internal combustion to mild and full hybrid to all-electric vehicles. The use of the 48V solution will expand rapidly, as it is the only viable solution to vexing power problems.

Enabling this new architecture requires new cables, connectors, active (power-management integrated circuits) and passive (protection device) components, along with 48V Li-ion-based batteries. Perhaps, in a decade or two, the 12V battery will be a historical footnote only seen at antique car shows. But for the foreseeable future, both the 12V and 48V batteries and their buses will coexist and interact to provide essential power with high efficiency and low dissipation.