Signal Chain Design Considerations for the Data-Hungry World

By Mark Patrick, Mouser Electronics

With the emergence of the Internet of Things (IoT), leveraging high-performance computing in the cloud and on edge platforms, the applications we use to run everything from our personal wellness and mobility to the homes and offices we occupy all have a greater appetite for data. Thanks to this data, society is becoming smarter.

We are monitoring aspects of the physical environment around us through an increasing number and variety of sensors. These sensors generate signals that are often of low amplitude and inherently noisy. Often they will contain non-linearities and, in the majority of cases, they need to be converted from their real-world analog form into computer-ready digital values. Each signal chain that purifies and converts those raw measurements, so as to bridge from the sensor to the compute/processing resource, has a crucial role in giving life to the data demand.

Common Signal Chain Features

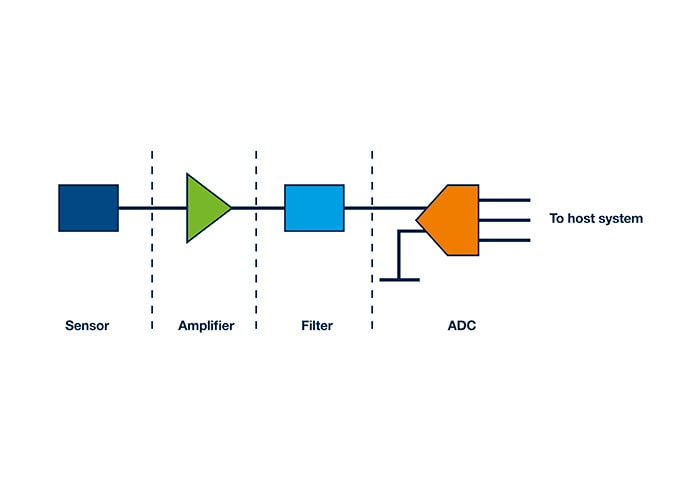

Generically speaking, a signal chain will comprise certain key elements. These are namely the sensor (or data acquisition hardware), signal amplification and filtering, followed finally by an analog-to-digital-converter (ADC) to sample and digitize the conditioned signal for subsequent processing or storage.

One or more amplifier stages might be required—such as a trans-inductance amplifier (TIA) followed by a voltage-gain amplifier. In addition, multiple filters might be needed to isolate the signal chain to within a certain frequency range, implement anti-aliasing for high-frequency signals and eliminate unwanted signals at specific frequencies (e.g. interference from the AC mains supply). Depending on the sensor's output it might make sense to amplify the signal before filtering, understanding that any noise will thus also be amplified. Alternatively, filtering can be applied first.

A successive approximation register (SAR), or sigma-delta ADC, might be best suited to the task of digitizing the filtered and amplified signal. SAR ADCs tend to have lower latency than sigma-delta devices, although the maximum sample rate is typically lower. Strengths of sigma-delta ADCs include high resolution and strong power efficiency, and additional features (such as filters, multiplexers, or input buffers) are often also integrated.

Figure 1: Generic signal chain components. (Source: Mouser Electronics)

Use Case of Industrial Temperature Monitoring

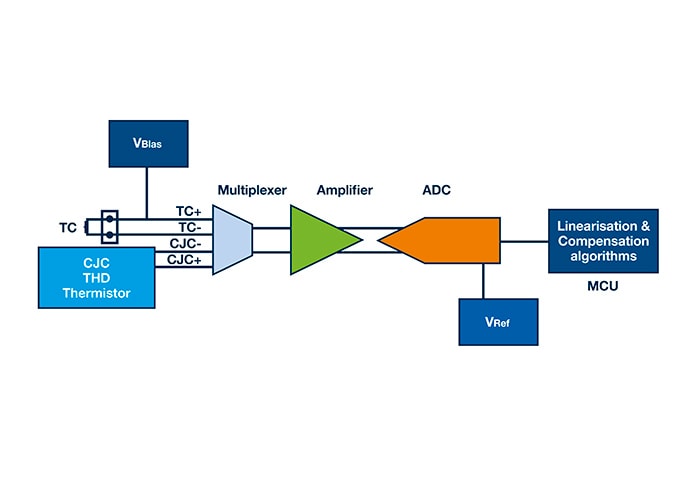

Temperature is said to be the most commonly monitored aspect of the physical world. A thermocouple can detect extremely high temperatures in industrial applications, but the output voltage is small (typically only a few mV). The signal chain components (as shown in Figure 2) must ensure high amplifier gain with low noise and low drift.

A reference temperature must also be monitored to provide cold junction compensation (CJC), allowing the instrument to generate an output voltage corresponding to the temperature sensed at the thermocouple probe. CJC is often implemented using either a resistance temperature detector (RTD) device or a silicon-based temperature sensor. An RTD requires an excitation voltage, which the signal chain design utilized must provide.

Thermocouples, RTDs, and thermistors all display inconsistent linearity that must be corrected somehow within the signal chain. As far as thermocouples are concerned, the change in output voltage for a given change in temperature is determined by the Seebeck coefficient. Because this coefficient is not constant across the thermocouple's operating temperature range, it is best to choose a type that offers the most linear response possible across the temperature range in which it will be working. For this, design engineers can refer to Institute of Printed Circuits (IPC) categories that standardize the properties of various types of thermocouples. As an example, an IPC type S thermocouple offers a useful temperature range from about 0°C to 1500°C and displays reasonable linearity from about 900°C to 1250°C. Reference tables for standard thermocouple types, such as those published by the American National Institute of Standards and Technology (NIST), enable linearity to be corrected digitally, saving the complexity of linearity correction within the signal chain itself.

Figure 2: An example of a thermocouple signal chain. (Source: Mouser Electronics)

Because each physical electrical connection to the thermocouple unavoidably creates an additional thermojunction, care must be taken to ensure that all connections except the temperature sensing probe and the cold junction are the same temperature.

Use Case for Medical/Fitness Monitoring

With the growing desire for self-quantification, as well as faster, more cost-effective healthcare, there is demand for easier sensing of bio-indicators (such as body temperature, blood oxygen, and heart rate) using either clinical-grade instruments or consumer-type devices (such as wristband trackers). Compared to thermistors and RTD temperature sensors, which require substantial signal processing, silicon-based temperature sensors offer greater linearity, stability, and ease of use. Although they have a narrower temperature range (typically from -20°C to 70°C), this is more than adequate for body-temperature monitoring by medical devices and wearables.

Maxim's MAX30208 is a clinical-grade digital temperature sensor that is optimized for straightforward, non-invasive body-temperature measurement. The temperature level is measured at the top of the package—which is easiest to place against the skin surface and least affected by self-heating issues (because of supply current entering via the IC pins). Pinning is optimized to allow mounting on a flexible printed circuit that can be positioned remotely from the host processor, and the I2C interface allows daisy-chaining of multiple sensors to capture data at several points on the body for optimum accuracy. The MAX30308 measures body temperature to within ±0.1°C and contains integrated signal chain circuitry and a 32-bit FIFO to simplify interaction with the host processor.

As far as monitoring heart activity is concerned, clinical-grade monitors have traditionally relied on electro-cardiographic (ECG) signals from multiple sensors attached to the body. More recently, optical photo-plethysmographic (PPG) sensing has developed to provide acceptable accuracy from a small, non-invasive wearable device—such as a fitness wristband or finger-clip pulse oximeter. PPG sensing works by transmitting light through body tissue and measuring the reflected or transmitted signals. Small changes in blood volume can be quantified, enabling indicators (including blood oxygen saturation, heart rate, and respiration) to be calculated. It is also possible to make inferences about tissue condition and organ fucntion.

The voltage signal from a PPG instrument's optical sensors contains a DC component related to blood volume and the optical properties of bone and tissue, with an AC component caused by changes in blood volume that correspond to the heartbeat. Other small signals generated by activity (such as respiration) are also present.

Designing the signal chain for a wearable heart-rate monitor begins with the transmitter, which can be a green LED or a combination of red and infrared LEDs. the wavelength and intensity of the source determine the depth of penetration and received signal strength, and can be adjusted for optimum accuracy. On the other hand, LED drivers introduce noise to the transmitted signal and power consumption must be considered, too.

The receive-side signal chain has to sample the photodetector output, handle ambient light cancelation, filter the signal, and do the ADC. The photodetector output is a current signal whose amplitude could be less than a nA or up to a few tens of μA. A transimpedance amplifier (TIA) is needed to convert the current signal into a voltage, and the design of the signal chain must take into account factors such as the signal dynamic range, signal-to-noise ratio (SNR), board utilization, and power consumption associated with elements such as anti-aliasing filters and the TIA. Fortunately, the large and growing market for wearable consumer-grade heart-rate monitors means engineers can opt for an integrated analog front end (AFE)—such as the AFE4490 from Texas Instruments or Maxim's MAX30110/12, which each incorporate the LED driver and a complete photodetector signal chain within their respective single-chip solutions. These devices provide a convenient mechanism for overcoming challenges such as manipulating the photodiode current, filtering, buffering, amplification, and converstion using a sigma-delta ADC.

Use Case in Imaging

Parameters such as human heart rate and industrial process temperatures are relatively simple and stable, placing only moderate demands on the signal chain as far as speed and sample rate are concerned. The MAX30110/12 supports a sample rate of up to 3.2kSPS—so as to meet the needs of a pulse-oximetry or heart-rate monitoring application. The signal speeds and sample rates in applications such as image sensing or industrial machine vision are much greater and require special consideration.

Simple imaging systems, such as near-infrared spectroscopy equipment for inspection or materials analysis, can employ a linear photodiode that requires cooling to minimize the effects of thermal noise and signal conditioning. The Analog Devices ADA4807 precision low-noise amplifier has a -3dB bandwidth of 180MHz and is well suited for use with the company's ADAQ7980 single-chip data-acquisition system that contains a 1MSPS low-noise SAR ADC with which power scales alongside sampling rate—maximizing efficiency. This device relieves design engineers of unwanted challenges such as circuit layout and component selection by integrating a high-bandwidth ADC driver that has low input noise and rail-to-rail output to minimize distortion. The internal power architecture and provision for an external precision voltage reference also contribute to preserving signal integrity by lowering system noise.

Machine vision with high-speed cameras and video surveillance applications are placing even grater demands on signal acquisition. A high-speed frame grabber implements the connection to the camera and interfaces to the host PC (typically over PCI or PCI Express) using a communication protocol such as Camera Link that defines video throughput rates from 255Mbps to 680Mbps. The frame grabber also typically implements important video pre-processing functions—such as gain control, defective pixel compensation, and dynamic range extension. These often need tbe done at real-time frame rates. Designing a frame grabbber is a significant engineering challenge, often implemented using FPGAs that provide the signal processing performance required and are also able to host machine vision algorithms on the same device.

Conclusion

Capturing signals from sensors to create informative data for any application, whether it is consumer, industrial, or all the way through to medical, requires a good understanding of each of the constituent components in the signal chain. this covers everything, starting with the sensor and going right up to the ADC, and in each case the correct items need to be chosen and then properly integrated. In many circumstances, a single-chip front end is already available, which can effectively simplify design and shorten the time-to-market.