Thermal Energy Harvesting - Infinite Clean Power for Wireless Sensor Networks

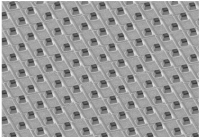

Thermoelectric micro-structures generate high voltages MEMS and micro system technologies make today's sensors inexpensive, energy efficient and precise. With modern ultra-low power wireless technology they can be deployed almost anywhere. Better visibility of operating and health states of assets and production equipment are attractive benefit of this increasing technology convergence. This leads to more energy efficient buildings, safer and more efficient production processes, and largely reduced maintenance costs. However, maintenance of thousands and thousands of batteries on a regular basis gets in the way of this bright new world. Energy harvesting holds the promise of replacing batteries with green, sustainable, maintenance-free, virtually infinite power for wireless devices. Thin Film Maximizes Voltage Micropelt Thermogenerator Chip MPG-D751 Micropelt, Freiburg, Germany based thermal energy harvesting specialist develops and commercializes thin film thermoelectric elements based on the company's patented micro-structuring processes, combined with semiconductor production technology. The combination allows for 50 thermocouples per mm². As a result the voltage per mm² is 200 to 400 times higher than that of legacy TEGs, giving an ideal starting point for efficient conversion to useful battery-like operating voltages. Inherent economies-of-scale of wafer production let micro-TEG unit costs decrease with growing production volumes. Micropelt's first volume fab is currently being ramped-up. Easy EvaluationAs a blueprint for a fully autonomous self-sustained wireless sensor node, Micropelt has designed the wireless evaluation system TE-Power NODE. This eval system modularizes that concept in order to facilitate the initial steps into thermal energy harvesting. The TE-Power NODE system got a high degree of flexibility so it can provide the necessary foundation for engineers tasked with the evaluation of thermoharvesting powered systems. The TE-Power NODE can also be used to power external wireless applications which do not require a real-time update rate and run low power protocols. A generic, configurable interface module facilitates this task.  Autonomous modular wireless sensor and thermoharvesting evaluation system TE-Power NODE The TE-Power NODE operates from a minimum gradient of 8 to 10°C between the warm surface and ambient air. The PC interface TE-Power SCOPE displays data from up to five NODEs connected through a USB receiver. Users can assess the particular harvesting location's thermal behavior over virtually unlimited periods of time. The generated power is converted to an annual primary battery capacity. Thus, a specific instrument's battery consumption can be compared to the momentary thermoharvester performance to find out if the harvester can replace a specific instrument's battery pack. Additional digital sensors can be attached to the TE-Power NODE's wireless module via its I²C bus interface. Flexibility is Key - External Power SourceOptimal locations for measurements and thermal energy harvesting are often not identical. A remote, short-wired harvester is an obvious need. Micropelt recently released their first commercial thermoharvesting power supply, TE-Power PROBE. The performance optimized device goes to a harvestable hot spot nearby without limiting the optimal positioning of a sensor.  External Thermoharvester TE-Power PROBE A hot side of 90°C (194°F) in a 25°C (77°F) ambient produces around 10 mW including 30% conversion losses - in other words: 30 AA cells annually.  Location for thermoharvesting field test at Shell facility Thermoharvesting recently caught the attention of Royal Dutch Shell. The oil multinational which produces gigawatts of waste heat wanted to prove the concept of clean, sustainable, maintenance-free power for wireless sensor devices. Shell's team used a Micropelt TE-Power PROBE buffered by a thin film battery to power a prototype Emerson Rosemount wireless pressure transmitter running WirelessHART, an industrial ISO standard mesh networking protocol. Average power consumption of this device is about 2.2 milliwatt. The set-up worked flawlessly for the 2 weeks it was left out in the field, transmitting data every minute to the associated Emerson wireless gateway.

|