SiC Powers Electrification

Image Source: VinStock stock.adobe.com; generated with AI

By Marcel Consée, Mouser Electronics

Electrification is key to the global transition to sustainable energy systems, and silicon carbide (SiC) power electronics play a pivotal role in this development. SiC, a wide bandgap (WBG) semiconductor material, offers substantial performance advantages over traditional silicon (Si) in high-power and high-frequency applications. It is particularly suitable for electrifying transportation, industrial systems, and renewable energy infrastructure.

The fundamental advantage of SiC lies in its material properties, with a bandgap of approximately 3.26 electron volt (eV), compared to 1.12 eV for silicon. This wide bandgap allows devices to operate at much higher voltages, temperatures, and switching frequencies. SiC also exhibits higher thermal conductivity, enabling better heat dissipation and more compact device packaging.

One of the most impactful benefits is reduced switching and conduction losses. SiC MOSFETs and diodes switch faster and with lower energy losses than their Si counterparts. This leads to higher efficiency in power conversion systems, directly translating into reduced energy consumption and less need for thermal management components such as heat sinks and cooling systems.

Applications in Transportation

In electric vehicles (EVs), SiC power electronics are used in traction inverters, onboard chargers (OBC), and DC-DC converters. SiC-based inverters can operate at higher frequencies and efficiencies, resulting in smaller, lighter, and more efficient powertrains. This contributes to longer driving ranges and faster charging times.

For example, replacing a silicon-based 400V inverter with a SiC-based 800V system allows for improved power density and system efficiency, reducing overall energy losses during vehicle operation. This approach also simplifies the thermal design, enabling more compact packaging and reducing system weight, both critical factors in EV performance.

Moreover, the fast switching capabilities of SiC devices facilitate the design of higher-frequency powertrains, which can reduce the size and weight of passive components like inductors and capacitors. These improvements enhance vehicle performance and lower the total cost of ownership over time.

Industrial and Renewable Energy Use

SiC power devices also transform power conversion systems in industrial motor drives, solar inverters, and energy storage systems. In photovoltaic (PV) applications, SiC enables smaller, more efficient inverters that can be placed closer to the panel arrays, minimising losses and simplifying system architecture.

SiC-based converters support faster switching, bidirectional power flow, and improved power quality in energy storage and grid-tied inverters. The higher efficiency and reduced cooling requirements lower the operating costs and increase the reliability of these systems.

In industrial automation, SiC helps improve the performance and efficiency of variable-speed drives and high-voltage power supplies. This leads to better productivity, reduced downtime, and enhanced energy savings.

Isolated Power Topologies for PLC I/O Modules

Designers of programmable logic controller (PLC) I/O modules or other industrial low-power applications need a reliable design for the proper and safe operation of their designed circuits under the conditions of a harsh industrial environment. Isolated power converters are frequently found in such applications and help in the following:

- Avoiding or breaking potential ground loops

- Avoiding coupling between adjacent channels or modules

- Providing electrical safety

The SN6507 (Figure 1) by Texas Instruments is a high-voltage, high-frequency push-pull transformer driver providing isolated power in a small solution size. The device offers the push-pull topology’s benefits of simplicity, low electromagnetic interference (EMI), and flux cancellation to prevent transformer saturation. Further space savings are achieved through duty-cycle control, which reduces component count for wide-input ranges, and by selecting a high switching frequency, reducing the size of the transformer.

Figure 1: Texas Instruments SN6507/SN6507-Q1 Push-Pull Transformer Driver. (Source: Mouser Electronics)

The device integrates a controller and two 0.5-A NMOS power switches that switch out of phase. Its input operating range is programmed with precision undervoltage lockouts. Over-current protection (OCP), adjustable under-voltage lockout (UVLO), over-voltage lockout (OVLO), thermal shutdown (TSD), and break-before-make circuitry protect the device from fault conditions.

The programmable Soft Start (SS) minimises inrush currents and provides power supply sequencing for critical power-up requirements. Spread Spectrum Clocking (SSC) and pin-configurable Slew Rate Control (SRC) further reduce radiated and conducted emissions for ultra-low EMI requirements.

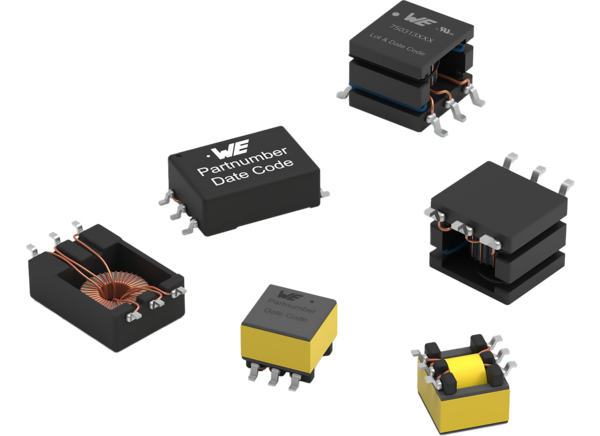

Those drivers are used in the WE-PPTI Push-Pull Transformers (Figure 2) by Würth Elektronik. They offer a high isolation voltage of 2.5kV. The WE-PP transformers for Texas Instruments SN6505 drivers feature a 120kHz to 480kHz frequency range and 1A current rating. The SN6501 push-pull drivers are designed for small transformers used in a variety of applications, such as isolated interfaces or low-power LAN.

Figure 2: Würth Elektronik Push-Pull Transformers for TI SNxx Drivers. (Source: Mouser Electronics)

Würth Elektronik also provides the SN6507 Development Kit, which allows for testing and assessing the performance of a push-pull auxiliary supply with different configurations (Figure 3).

The kit includes two boards: a fixed board (650796) offering 24 VIN–15 VOUT with transformer 750319696, and a configurable board (650700) designed to support various application needs by allowing users to select between 16 different transformers included in the kit.

It is intended for use in evaluating the SN6507 for applications such as motor drives, isolated power supplies for communication protocols (CAN, RS-485, RS-422, RS-232, SPI, I2C), medical instruments, solar inverters, and automation systems, amongst others.

These SN6507 are tiny push-pull transformers with 12V and 24V Inputs, operating in the temperature range of -40°C to +125°C.

Figure 3: SN6057 evaluation boards in fixed (left) and configurable (right) versions. (Source: Mouser Electronics)

A Sustainably Electric Future

Despite its advantages, the adoption of SiC power electronics comes with its own challenges. The fabrication of SiC wafers is more complex and expensive than that of silicon. However, recent advances in crystal growth, device fabrication, and supply chain scaling have rapidly improved yield and reduced costs. SiC power electronics represent a transformative technology for the electrification of modern energy and transportation systems. Their high efficiency, compactness, and thermal performance enable new design flexibility. As production matures and costs decline, SiC will continue to accelerate the shift towards a more electrified, energy-efficient, and sustainable future.

About the Suppliers

Texas Instruments

Texas Instruments has been making progress possible for decades. TI is a global semiconductor company that designs, manufactures, tests, and sells analog and embedded processing chips. The company's approximately 80,000 products help more than 100,000 customers efficiently manage power, accurately sense and transmit data, and provide the core control or processing in their designs, going into markets such as industrial, automotive, personal electronics, communications equipment, and enterprise systems. TI's passion to create a better world by making electronics more affordable through semiconductors is alive today as each generation of innovation builds upon the last to make our technology smaller, more efficient, more reliable, and more affordable - opening new markets and making it possible for semiconductors to go into electronics everywhere. TI thinks of this as Engineering Progress. It’s what TI does and has been doing for decades.

Texas Instruments has been making progress possible for decades. TI is a global semiconductor company that designs, manufactures, tests, and sells analog and embedded processing chips. The company's approximately 80,000 products help more than 100,000 customers efficiently manage power, accurately sense and transmit data, and provide the core control or processing in their designs, going into markets such as industrial, automotive, personal electronics, communications equipment, and enterprise systems. TI's passion to create a better world by making electronics more affordable through semiconductors is alive today as each generation of innovation builds upon the last to make our technology smaller, more efficient, more reliable, and more affordable - opening new markets and making it possible for semiconductors to go into electronics everywhere. TI thinks of this as Engineering Progress. It’s what TI does and has been doing for decades.

Würth Elektronik

Würth Elektronik eiSos GmbH & Co. KG is a manufacturer of electronic and electromechanical components for the electronics industry and a technology enabler for future-oriented electronics solutions. Würth Elektronik is part of the Würth Group, a world leader in assembly and fastening technology. The product portfolio of Würth Elektronik eiSos includes EMC components, inductors, transformers, RF components, varistors, capacitors, resistors, crystals, oscillators, power modules, wireless power transfer, optoelectronics, sensors, radio modules, connectors, REDCUBE terminals, switches and buttons, assembly technology, and thermal management.

Würth Elektronik eiSos GmbH & Co. KG is a manufacturer of electronic and electromechanical components for the electronics industry and a technology enabler for future-oriented electronics solutions. Würth Elektronik is part of the Würth Group, a world leader in assembly and fastening technology. The product portfolio of Würth Elektronik eiSos includes EMC components, inductors, transformers, RF components, varistors, capacitors, resistors, crystals, oscillators, power modules, wireless power transfer, optoelectronics, sensors, radio modules, connectors, REDCUBE terminals, switches and buttons, assembly technology, and thermal management.