MEMS Oscillators

By Syed Raza, Director of Engineering, Abracon

Historically, reference oscillators used to clock a Phase Lock Loop circuit; providing a reference signal to any timing related circuit has predominantly utilized quartz crystals as the core resonators. The degree of difficulty associated with reducing the form-factor of these devices, while keeping the cost down, has been challenging. Further, for wider temperature range solutions requiring tighter stabilities, crystal oscillators still tend to cost more than what the market is willing to bear. The newest generation of MEMS oscillators effectively address both of these challenges.

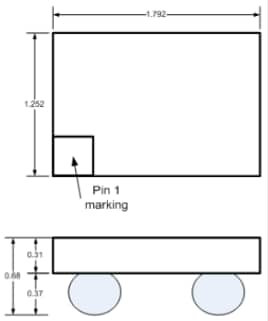

Figure 1

Micro-Electro-Mechanical-System (MEMS) based devices were first manufactured in the mid-1960’s. Since then, the technology has evolved to the point that it is now possible to offer temperature stabilized MEMS Oscillators in extremely small form factors.

Modern day MEMS Oscillators are constructed utilizing Silicon Wafer processing techniques. Significant advances in the creation of miniature MEMS Resonator structures have enabled the manufacturing of accurate clock oscillators. These devices are now readily available in standard oscillator footprints, including 5x7mm, 5x3.2mm, 2.5x2.0mm, and now, compatible to 1.6x1.2mm.

Figure 2

Advanced circuit topologies are employed to offer both CMOS as well as differential clock outputs, both LVDS & LVPECL. Further, these devices are optimized for low voltage operation, down to +1.8V standard logic levels.

A simplified block diagram of a LVCMOS MEMS Oscillator is shown in figure (1). This architecture has been successfully implemented in a Ball Grid Array package, measuring a mere 1.792x1.252x0.68 mm.

The latest MEMS Oscillator offering shown in figure (2) is designed to fit the industry standard oscillator footprint of 1.6x1.2x1.0 mm. Utilizing proprietary resonator technology, this device is available in mass volume with the following key attributes:

| Available Resonant Frequency Range | 1.00MHz to 156.25MHz |

| Bias Voltage | +1.70V to +3.60V |

| Operating Temperature Range (OTR) | -40ºC to +105ºC |

| Frequency Stability over OTR | ±10.0 ppm available (±25 ppm & ±50 ppm as options) |

| Period Jitter (rms) | 6.0ps typical, 7.0ps maximum |

| Cycle-cycle Jitter (rms) | 11.0ps typical, 12.0ps maximum |

| Current Drain | 9.6mA @ 156.25MHz with Vdd=+3.6V / 6.9mA @ 156.25MHz with Vdd=+1.7V |

The ASCSM family of MEMS Oscillators are configured to address any frequency need between 1.0MHz and 156.25MHz. Since these devices are factory configurable, customers can indicate any desired frequency and it can be produced immediately. Due to the standard wafer processing techniques, high volume demand can be satisfied in a matter of weeks rather than months, which is generally associated with crystal oscillators at non-standard frequencies.

Figure 3

This advanced series of MEMS Oscillators employ a traditional Fractional Synthesis approach, coupled with a temperature correction circuitry. This technique enables the availability of ±10 ppm temperature stability over a wide operating temperature range of -40ºC to +105ºC. Figure (4) depicts the typical temperature error for Abracon’s ASCSM series of MEMS Oscillators.

In summary, MEMS Oscillators have evolved to provide low cost, quick turn reference clock solutions generally available from 1MHz to 460MHz with either LVCMOS or LVDS/LVPECL outputs. The miniature ASCSM series presented here is currently available with an LVCMOS output from 1MHz to 156.25MHz.

Figure 4