Harsh Environments Challenge Power Management

By Lynnette Reese, Mouser Electronics

The possibility of extreme cost savings that data-based predictive modeling brings to the industrial world of system monitoring and control will further the automation of factories and manufacturing and assist in refurbishing transportation and energy transmission infrastructure. The need for data will require carpeting the industrial world with high-resolution components connected to the Internet of Things (IoT). But in spite of advances in industrial IoT, consideration for harsh environments still remains critical in the humble form of enclosures and power management.

Entirely new business opportunities from the analysis of IoT-generated data can come from sensors and controllers, especially in harsh environments (HE). General Electric’s (GE) Jet Engine business, for example, has been dramatically transformed by the use of predictive models. This new “digital industrialization” accesses, interprets, and analyzes terabytes of performance data, transforming it into cost savings and greater productivity in part by modifying maintenance and repair schedules. GE’s efforts don’t end with jet engines. GE will “reap $1 billion in added productivity from its operations as more factory and design processes are fed into digital systems that improve collaboration and speed up production cycles,” according to the Wall St. Journal.i

Figure 1: Amphenol® Industrial offers KTK High Pressure Downhole Connectors as a line of high pressure connectors ideal for Oil and Gas Drilling applications. Image by Amphenol Industrial.

But GE has no monopoly on measuring the impact of harsh environments on electronic systems. The oil and gas industry has long used “downhole” electronics, connectors and devices that must withstand temperatures as high as 200°C (415°F) and pressures as high as 30,000 pounds per square inch (PSI). Yet there are many other applications in which the electronics must be protected from harsh environments

Protecting power rails is particularly challenging, in ensuring the integrity of electronic systems. Even if the power supply is not operating at the tip of an oil well drilling probe, industrial environments can be threatening to the longevity of electronics. Power management devices must provide precise control of voltages, even under horrendous current loads. These devices are the building blocks for power supplies, pulse motor controls, and auto ignition systems.

Not surprisingly, market research firms have identified industrial controls as the primary market driver for power management controllers (voltage regulators, motor drivers, pulse and spark generators) — displacing computer power supplies as the primary consumer of power management chips and modules. Industrial and computing markets each consume about $3.5 billion in power management semiconductors per year.

Compared to the parts used in computer and communications data centers, industrial power management devices must operate at higher voltages (which increases the difficulty of waveform control, and challenges energy transfer efficiency). Anything that interfaces with a three-phase 220VAC powerline, for example, must be rated for 600 volts or more. Chances are — despite the demand for high energy transfer efficiency — large heat sinks will be required. The additional challenge for industrial power control is an ability to maintain speed, precision, and efficiency in harsh environments.

The Challenge of Harsh Environments

Electronics that are designed to operate in harsh environments often surpass military specifications (i.e., -40°C to 125°C). Ruggedized enclosures must protect electronic circuitry from exposure to liquids, particles and tampering. The two most relevant enclosure specifications include the National Electrical Manufacturers Association (NEMA) ratings and the almost-equivalent Ingress Particulate (IP) code (IEC 60529). These documents effectively quantify the degree to which a product can withstand various harsh conditions (such as dust storms or emersion in corrosive liquids.)

NEMA enclosure standards actually specify the degree of protection the enclosure provides. Depending on which document you consult, a NEMA Type 1 enclosure will either protect workers inside from falling dirt and stones, or serve as a barrier to keep them from handling the electronic circuitry inside. The degree of protection, as well the restriction of access, increases with NEMA ratings numbers. A Type 3 rating, on the other hand, provides a degree of protection from the ingress of water (rain, sleet, snow) — or the formation of ice on the outside of the enclosure. Cellular base stations, often sealed canisters mounted on telephone poles, reflect NEMA 4X ratings. Type 12 specifies enclosures intended for use in dusty industrial applications with additional protection from non-corrosive liquid drips.

| Rating | Uses | Description |

| 4 & 4X | GENERAL PURPOSE WEATHER-PROOF | Intended for use indoors or out doors with protection from wash down environment and corrosion resistance. |

| 6 & 6P | GENERAL PURPOSE SUBMERSIBLE | Intended for use indoors or outdoors with protection from occasional submersion. |

| 7 | HAZARDOUS | Intended for indoor use in Class I, Groups A, B, C, and D environments per NFPA rating system. |

| 8 | HAZARDOUS | Intended for indoor or outdoor use in Class I, Groups A, B, C, and D environments per NFPA rating system. |

| 9 | HAZARDOUS | Intended for indoor or outdoor use in Class II, Groups E, F, and G environments per NFPA rating system. |

| 12 & 12K | INDUSTRIAL | Intended for use in industrial applications with protection from dust and non corrosive liquid drip. |

| 13 | INDUSTRIAL | Intended for use in industrial applications with protection from dust, spraying water, oil and non corrosive liquid drip. |

Table 1: Enclosures listed by NEMA Rating

The IP standards are a bit more explicit. The IP-68 environment, for example, specifies “permanent emersion” in liquids as much as 3 meters deep, and a total seal against dust.

In addition to particle ingress, electronics can be easily damaged or rendered inoperable if exposed to water or other liquids. Automotive engine compartments are especially vulnerable. Mounted in systems just under the hood of a vehicle, electronic components are exposed to vibration, heat, humidity, water, mud and motor oil.

Protecting Your Power Rails: Examples to Consider

Figure 2: Mean Well's HEP-100 Series industrial-grade power supplies resist 6KV surges, and can be potted for IP68 moisture resistance. Image: Mean Well.

While selecting an enclosure is necessary in protecting circuits from wet and dusty environments, don’t overlook the reliability and service record of power sources. The Mean Well HEP-100 is an industrial power supply intended for harsh environments and elevated temperatures (-55°C to +70°C). This is an AC/DC power supply with up to 94% efficiency. Five versions are available, with 100-, 150-, 185-, 240-, or 320-watt outputs. The HEP supplies accept a wide input range (90 to 305VAC) and offer output voltages of 12V, 15V, 24V, 36V, 48V, or 54V, making the series scalable across many applications.

The 320-watt version offers enough power to run programmable logic controllers in factory environments (or for server cards with high on-time duty cycles). The switching supply includes short circuit, over voltage, and current overload protection. It resists current surges up to 6kV. These power supplies are potted with heat-conductive silicone and provide up to IP68 protection against the ingress of dust and water (completely sealed) and up to 10G in vibration resistance. The series is suited for outdoor telecommunication equipment, outdoor signage and billboards, and petroleum plants or mine shaft facilities.

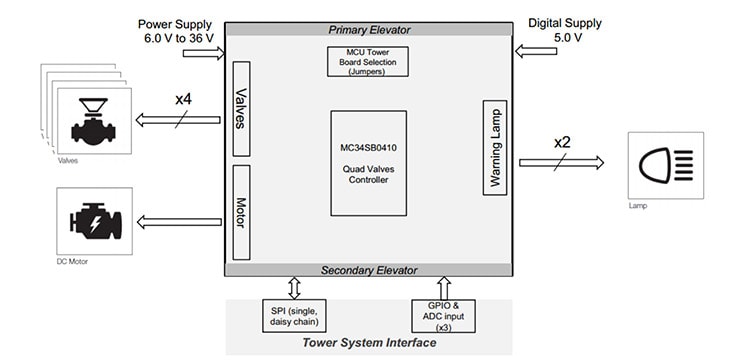

NXP Semiconductor’s SB0410 is a different kind of power management device. The industrial motor controller on a chip is a quad valve and pump controller system-on-chip (SoC). It includes four low-side regulated solenoid drivers and a high-side pulse width modulator (PWM) to control a pulsed DC motor (with the aid of outboard MOSFET power transistors). The device is protected from loads with high inrush currents. The pulsed motor drive circuits will deliver up to 2.25A (with 5.0 kHz pulses).

Figure 3: NXP Semiconductor’s SB0410 is an industrial controller chip is a quad valve and motor drive system-on-chip (SoC). It includes four low-side regulated solenoid drivers and a high-side pulse width modulator (PWM) for motor drive. Image: NXP.

For harsh environments, the NXP SB0410 includes a die temperature warning. HE applications as identified by NXP include spot welding, laser cutting, bottle molding, heavy equipment and construction machinery, and fork lifts. Other applications include irrigation control systems.

Power management is always necessary for electronics in harsh environments, since all active electronics require power. One very common example is the high operating temperatures and high vibration environment inherent in automotive electronics. Infineon Technologies’ AEC-qualified TLF80511EJ LDO Linear Regulator uses a conventional series pass topology, for load currents up to 400mA. Low operating currents allow the parts to be permanently connected to a battery without overload. A low quiescent current (38µA) for this device prevents battery drain. Thus, these otherwise conventional regulators are great for automotive instrument clusters.

Specifically intended for automotive applications, the part operates from -40°C up to 150°C. Other automotive applications include Electronic Control Units (ECU), automotive dashboards, climate in-cabin (HVAC), and start-stop engines.

Conclusion

Maintaining specified voltage levels under often severe current loads remains the on-going challenge for power management devices. Voltage converters and regulators are additionally tasked with maintaining high energy transfer efficiency to prevent heat generation. Harsh environments that demand controlled electronic system performance in tightly-sealed enclosures only complicate requirements. Engineers must be careful to specify only those components that are fully up to the task.

iTed Mann, “GE Bullish on Data for Big Industry,” Wall Street Journal, 23 June 2016. Web. 1 July 2016.