All Aboard! Industrial IoT Powers Today's Locomotives

By Bill Giovino, Mouser Electronics

Featured Products

Featured Manufacturers

Related Resources

A train pulled by a couple of locomotives can haul a ton of freight 500 miles on a single gallon of fuel. What makes this efficiency possible? A network of sensors distributed over the locomotive and the cars behind it. Today’s locomotives have up to 250 sensors that take in thousands of readings every minute. Modern locomotives are essentially rolling industrial power plants, and like all modern power plants, they benefit from the technology of the Industrial Internet of Things (IIoT).

Figure 1: The General Electric ES44DC Locomotive is a fully-automated industrial diesel powerplant on wheels, generating 4,400 hp (3,280 kW). It’s 250 sensors continuously monitor the engine and environment to automatically control throttle and brakes. (source: Wikipedia)

The main focus of Industrial IoT, sometimes referred to as Industry 4.0, is to improve efficiency by automating existing processes as much as possible. Industrial automation has always been quick to incorporate any new technologies that will improve efficiency. For example, programmable logic controllers (PLCs) replaced rows and rows of relays. Proprietary wired communications were replaced by Ethernet, which was quickly supplemented by WiFi. Application-specific embedded systems code was replaced by Microsoft Windows, and in some cases are now being replaced or supplemented with Android or iOS. Custom CRT consoles were first replaced by desktop PCs, which were then replaced by laptop PCs and those are now being replaced by mobile tablets connected by Bluetooth to the system for remote management. Imagine using a tablet computer to start or stop a 200-ton train!

Modern Manufacturing and Power Plants Using IIoT

The Industrial IoT is now the latest technology to revolutionize the modern factory. The most significant benefit is an increase in the operational efficiency of manufacturing facilities and power plants, and this has been the focus of the early adopters. For example, by automating some of the tedious processes that used to be performed by a human operator, manufacturers are able to dramatically improve efficiency while reducing error. Another significant use of sensors and IoT is predictive maintenance. This involves the monitoring of various components of the factory or power plant to determine if a component is close to failure. This allows the component to be replaced before it fails in an operating environment, preventing the high expense of downtime. Just by these two applications, automating existing processes and preventing downtime by predictive maintenance, the Industrial IoT is driving costs down while increasing production.

Industrial automation has always relied on sensors to measure pressure, fluid flow, temperature, vibration, position, location, presence, and more. Now those sensors are being implemented with more accuracy and less cost, because the latest advances in sensor technology allow sensors to be battery powered and connected wirelessly to the main system. This allows more flexibility in connecting sensors while also reducing the cost of the sensor network.

Modern Diesel Locomotives and IIoT

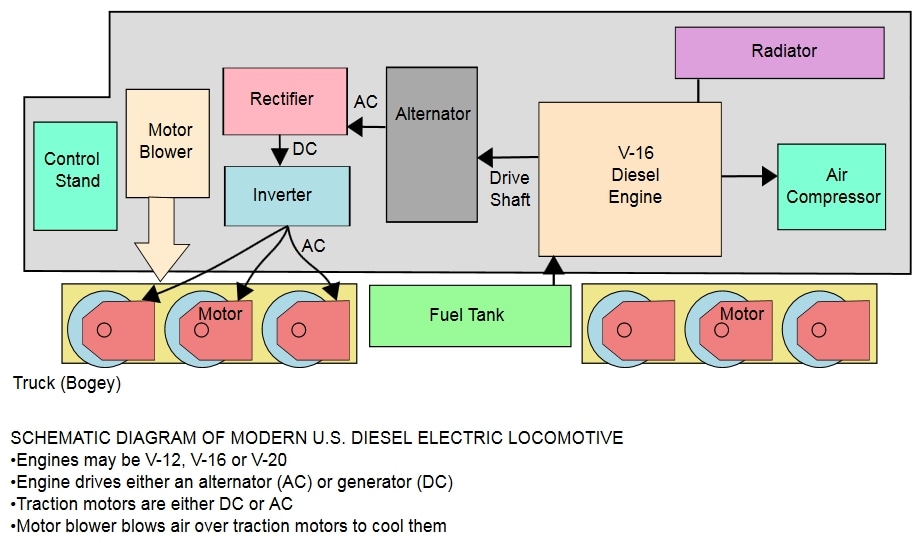

Today’s locomotives are truly examples of industrial automation in the extreme. The modern locomotive uses a diesel engine to drive either an alternator for AC current, or a generator for DC current, which powers the electric motors that drive the wheels. A prime example is the Evolution Locomotive manufactured by General Electric (GE). These locomotives feature over 250 sensors on the engine, cab, and surrounding areas. These sensors send over 150,000 real-time data points over the network each minute. Data processed includes engine temperature at various points including bearings and manifold temperature, oil pressure at various points in the massive diesel engine, speed of the train, and many others. Cameras on the front and around the train are fed to the computer for image recognition of problems or obstructions. External sensors measure weather including barometric pressure, wind speed and direction, temperature, and humidity. The condition and inclination of the track is also measured. The computer also controls auxiliary systems such as fans, lights, horns, and cabin air conditioning.

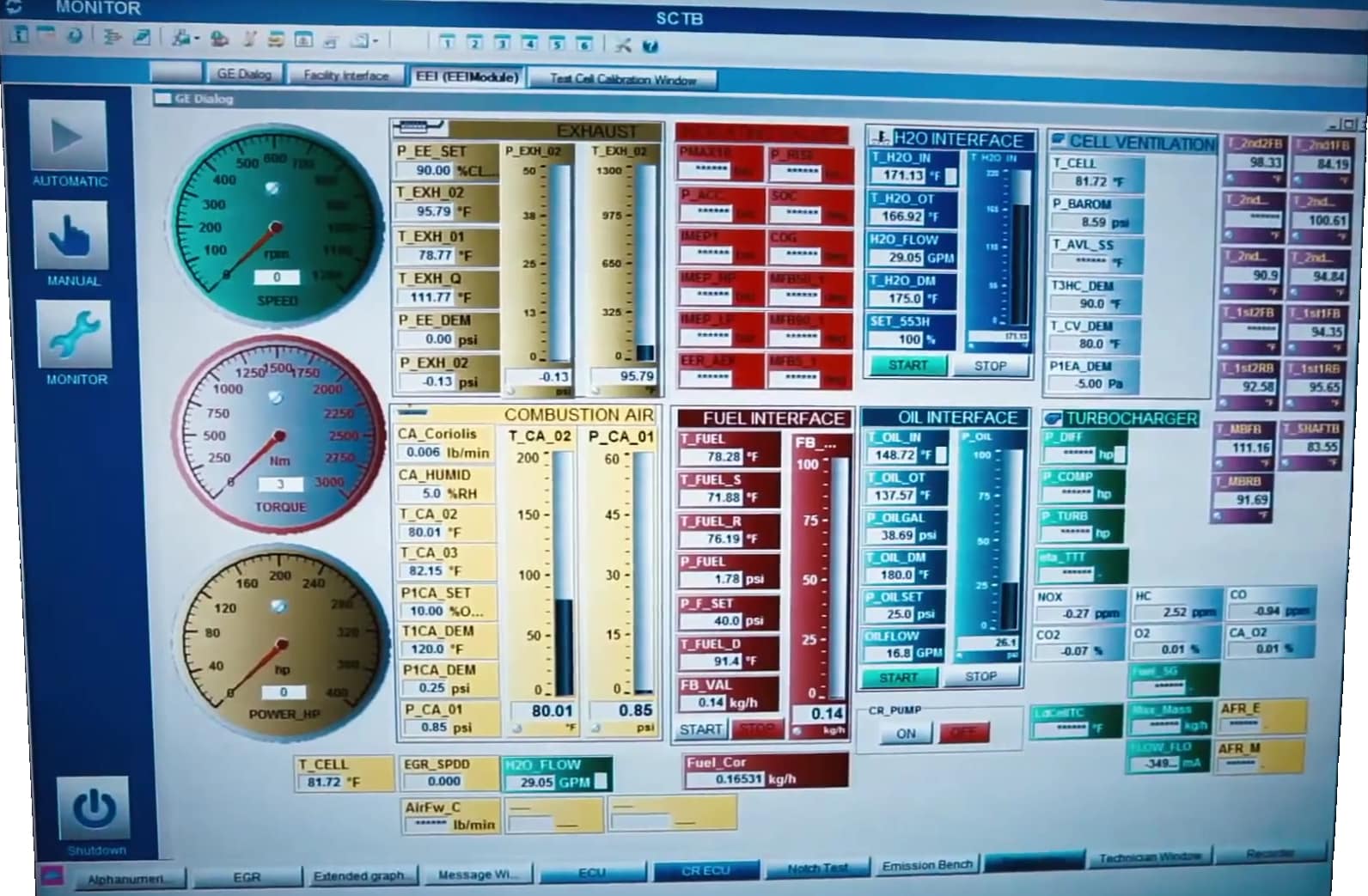

Figure 2: Cabin engine sensor display of a GE Evolution Series Locomotive. Over 100 sensors are displayed on this panel, including the exact air/fuel mix in the cylinders and the composition of the exhaust gasses. (Source: YouTube)

This constant monitoring of the engine’s status with real-time data allows total and precise automation of the locomotive, including automated control of throttle and braking. For example, Figure 2 shows how engine sensors measure the exact fuel-air mix so the computer can adjust the mix for maxim efficiency. This level of measurement and control contributes to the automation of the operation of the entire train with minimal human intervention.

Figure 3: Block Diagram of a Modern Diesel Locomotive (Source: Wikipedia)

Given the close relationship between the modern automated factory and today’s automated locomotives, it should come as no surprise that today’s locomotives are controlled by some of the same PLCs used in today’s factories. Ethernet is used as the backbone for the train’s VLAN networking with support for Modbus TCP/IP. Many sensors are assigned a localhost IP address, while the entire train communicates data to the railway’s cloud over radio and 4G networks. Industrial mobile phone routers from Phoenix Contact communicate over phone networks and are qualified for railway use.

Figure 4: Mobile phone routers are used to communicate wirelessly between the locomotive’s VLAN and the railroad’s headquarters (Source: Phoenix Contact)

Bus interfaces for the PLCs include Ethernet EGD, Genius, DeviceNet, and Interbus-S. FieldBus interfaces are popular as they are common in industrial environments because of their ease of use. A PLC found on many GE locomotives is the VersaMax Industrial PLCs from Phoenix Contact. These snap into a common DIN-rail backbone or can easily screw into a cabinet panel.

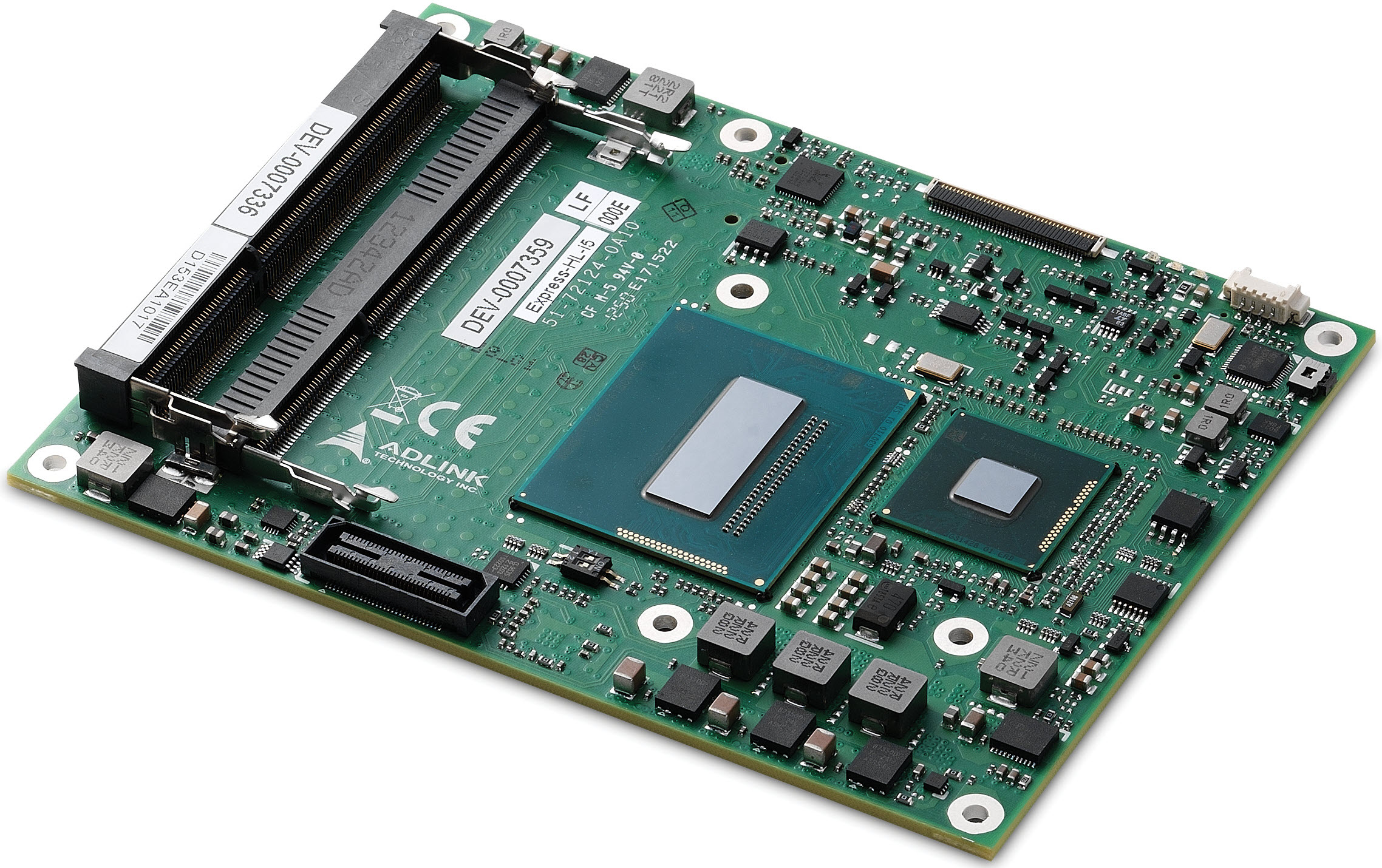

Modern locomotives also use single-board computers (SBCs) that use the popular COM Express bus, often used in edge nodes on the Industrial IoT system. These SBCs support Gigabit Ethernet networking and can connect to local peripherals such as printers with on-board USB connections. Code memory is easily changed by swapping out SD cards. It’s important to note that all of the computing equipment, hardware, and networking protocols are the same as used in factory automation.

Figure 5: Express-HL COM Express board by ADLINK are used in industrial automation as well as railways. (Source: ADLINK)

Automating Throttle, Brake, and Gear Control

The automated operation of throttle, braking, and selected gear ratio of the locomotive is based on precise sensor measurements of the train and its surroundings. Sensors measure wind speed and direction, and the effective force and direction against the train is calculated based on the weight, shape, and inertia of the locomotive and attached cars. The massive inertia of the train at that moment is vital to real-time control. Weather is also a factor, especially if there is rain or snow. The topology of the track is taken into account including if the train is on an upgrade, downslope, or level track. All this sensor data is fed to the locomotive’s computer system in order to help determine the correct throttle and braking control.

The trains horns and bells are required to sound in specific patterns during certain train events. For example, in the United States, when applying brakes while standing the horn sounds one short burst. When brakes are released in preparation to the train moving from a standing stop, the horn is required to sound two long bursts. When backing up, three short bursts of the horn are sounded. While in the past this was all done manually by the operator, in modern locomotives this is now controlled by the train’s computer.

Inside the locomotives driving the train is a massive diesel engine. The GE Evolution Series of locomotives use a massive 12-cylinder diesel engine that generates up to 6,200 horsepower (4,620 kW). The industrial grade on-board computer system automates the operation of the entire train in the same way as an automatic pilot on an aircraft. Throttle, brakes, and gearing are controlled based on sensor readings and compared to GPS data, the planned route, expected elevation changes, and the size and type of load. Efficiency is key here and everything is calculated to provide the best fuel economy possible.

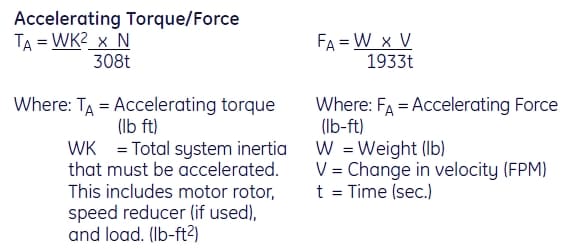

The basic formula for determining the accelerating torque and force of the train is below:

Formula 1: Calculating the accelerating torque and force of a massive train

Crucial to these calculations is all the sensor readings that are used to determine the massive total system inertia of the train, WK. While this is a single variable in the above formula, it is determined by taking into account the hundreds of sensors on the train which is run through sophisticated algorithms in the locomotive’s computer system. Only when this is correctly calculated, automation of the train’s throttle, brakes, and gearing becomes possible.

Deceleration is, of course, also automated and is especially important in emergency situations. If the train needs to slow down because the front camera imaging analysis has detected an obstruction, the front radar provides the closing distance to the obstruction to the locomotive’s computer system. The speed and total system inertia of the entire train at that moment is calculated, and the decelerating torque and force is determined. Based on the calculated optimum distance for stopping the train, the proper gear ratio and braking force is determined and the computer applies the brakes to stop the train. The computer will also have the horn sound repeatedly as a warning. If the computer determines that the train cannot slow down in time before reaching the obstruction, it automates sounding a cabin alarm to the operator while transmitting a message over the wireless communications network to railway headquarters that a collision is imminent.

Wheel slip is one of the weakest links in a locomotive’s operation. Excessive slip in the drive wheels results in reduced efficiency, decreased fuel economy, and can jeopardize the safety of the train. While in the past slip has been controlled solely by the skill of the driver, the industrial IoT system in today’s locomotives provides a highly effective way of minimizing this important issue. Slip is measured by comparing the actual speed of the locomotive, as measured by Doppler radar, to the rotation of the drive wheels, which is proportional to the motor current. If the two do not match, the train’s computer automates adjusting the motor current to insure maximum traction between the drive wheels and the track.

Maintenance and Efficiency

The computer also controls how much power flows to the electrical components of the locomotive. This includes the fans, battery chargers, blowers, lights, and edge computers. This control is also due to sensors that sense things like temperature, speed, and status of the batteries. This level of control improves the reliability of the engine while making the locomotive even more efficient. Predictive maintenance is another important feature of Industrial IoT. Wheel bearing temperature is measured and used to predict end-of-life of the bearings. Wheel shape is measured by sensors which can predict if a wheel is going to go out-of-round, or even if it is off the track.

The status of the entire train on the network is also measured. Each door, hatch, and gate is monitored or an open or close position and in many cases the computer can automate opening and closing. The hundreds of sensors themselves do self-diagnostics to determine if they need to be replaced before failure.

Every sensor reading, every action taken by the train, is logged by the computer in a box much like the “black box” found in aircraft. Later this data can be examined to uncover new ways to optimize train operations.

Conclusion

Modern diesel locomotives have come a long way from the manually-operated steam engines of a hundred years ago. Each locomotive is its own industrial power plant with hundreds of sensors, and its operation is automated in exactly the same way as stationary power plants. All this automation improves efficiency which saves millions of gallons of fuel, improves safety, and extends the life of today’s locomotives.