Automated Manufacturing Elevates Transformer Performance

New Tech Tuesdays

Join Mouser's Technical Content team for a weekly look at all things interesting, new, and noteworthy for design engineers.

Published July 1, 2025

Precision and consistency aren’t just desirable in power systems that demand isolation for reliability, safety, and flexibility—they’re essential. Whether it's driving a gallium nitride (GaN) field-effect transistor (FET) in a solar inverter or managing isolation in an electric vehicle (EV) charger, the components behind the scenes must perform flawlessly within a compact footprint. Enter the Bourns SM91243L, an advanced gate driver transformer engineered for high-performance applications. This week’s New Tech Tuesdays showcases how the SM91243L transformer fuses cutting-edge design for manufacturing (DFM) overmolding and fully automated manufacturing to redefine what’s possible in compact, high-voltage isolation components.

The Power of Automation

At the heart of SM91243L's innovation is its fully automated manufacturing process. Unlike traditional transformer production, which often involves manual winding and assembly, Bourns has embraced a DFM overmolding approach. This method ensures that every unit is built with precision winding and uniform insulation. With these features, automated manufacturing becomes enhanced with several key advantages:

- Repeatable quality: Every unit meets exacting standards with minimal variation.

- High reliability: Reduced human error means fewer defects and longer product life.

- Cost efficiency: Lower labor costs and faster production cycles translate to savings for both manufacturers and end-users.

In high-voltage applications like solar energy systems and onboard EV chargers, even minor inconsistencies can lead to performance degradation or safety risks. Automation mitigates these concerns by delivering tight control over critical parameters like interwinding capacitance (Ciw) and leakage inductance (Lk), which are key to supporting the fast-switching speeds of modern GaN-based gate drivers. In a general gate driver application, the role of these Bourns power transformers is to provide isolated transmission of both pulse width modulation (PWM) signal passing and gate bias power to the secondary side.

The Newest Products for Your Newest Designs®

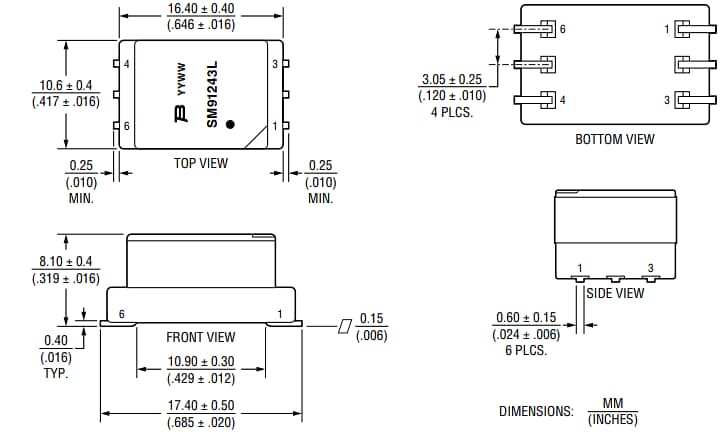

The SM91243L reinforced gate driver transformer from Bourns provides high isolation reliability in a compact size (Figure 1). With reinforced insulation, a 10mm creepage and clearance distance, and high-voltage isolation up to 5kVDC, verified through high-potential (Hi-pot) testing, the transformer is engineered to meet the rigorous demands of industrial, renewable, and automotive environments. And because every unit is produced under the same automated conditions, engineers can count on consistent high-voltage reliability across the board.

Figure 1: The Bourns SM91243L gate driver transformer offers reinforced insulation in a compact size, while being RoHS and REACH compliant. (Source: Mouser Electronics)

In addition to improving quality, automation also drives cost-effectiveness. By reducing labor costs, minimizing material waste, and accelerating production cycles for processes such as space-constrained designs, Bourns can deliver a high-performance transformer that’s also economically viable for high-volume markets like data centers, robotics, and clean energy.

This efficiency is especially important as the industry shifts toward wide bandgap semiconductors like GaN and silicon carbide (SiC), which demand compact, high-isolation components to unlock their full potential. The SM91243L is optimized for use with Allegro MicroSystems’s AHV85000 and AHV85040 GaN gate driver chipsets, making it a natural fit for next-gen AC-DC and DC-DC converters.

Tuesday’s Takeaway

The Bourns SM91243L reveals what’s possible when automation meets innovation. With its compact form factor, robust insulation, and automated precision, the SM91243L helps engineers build smarter, safer, and more scalable power systems. Whether designing solar, EVs, or industrial automation, this transformer delivers the performance and reliability that modern applications demand.