Power, Precision, and Protection in Industrial Automation

New Tech Tuesdays

Join Mouser's Technical Content team for a weekly look at all things interesting, new, and noteworthy for design engineers.

Published June 10, 2025

For industrial automation, precision isn’t just a perk—it’s a necessity. Whether controlling a high-speed motor or managing energy flow in a factory, accurate current measurement is the heartbeat of modern systems. This week’s New Tech Tuesdays examines how Allegro’s ACS3704x magnetic current sensors offer a smarter, safer, and more efficient way to monitor current in demanding environments.

Challenges in Traditional Sensing

For decades, engineers relied on shunt resistors and isolation amplifiers to measure current. While effective, this method comes with trade-offs, including power loss, heat generation, limited bandwidth, and complex isolation requirements. In high-frequency applications—like those found in industrial motor drives—these limitations can lead to inefficiencies, reduced accuracy, and increased design complexity.

Allegro’s Elegant Solution

The ACS3704x series from Allegro flips the script on current sensing by using Hall-effect technology to sense the magnetic field around a conductor. This approach allows the sensor to measure current indirectly, meaning there’s no need to interrupt the circuit or introduce power-hungry components.

Here’s what makes these leaded magnetic current sensors stand out:

- Galvanic isolation: The sensor provides complete electrical isolation between the high-voltage system and low-voltage control electronics, enhancing safety and protecting sensitive components.

- High bandwidth: With a bandwidth of up to 150kHz, it can track fast-switching currents with precision—ideal for modern motor drives and power converters.

- Lower power consumption: Unlike high ohmic shunt resistors, the current sensor leadframe doesn’t generate as much heat or waste energy, making the ACS3704x magnetic current sensors a more efficient choice.

- Compact design: Its small, rugged form factor is built for harsh industrial environments, saving space without sacrificing performance.

The Newest Products for Your Newest Designs®

ACS3704x magnetic current sensors provide galvanically isolated analog voltage outputs directly proportional to the measured current, eliminating the need for external shunt resistors. Featuring a low-resistance integrated conductor (as low as 1.6mΩ) and differential sensing, the ACS3704x series reduces power loss while effectively rejecting external magnetic interference. And with the improved thermal performance and heat dissipation of the Allegro ACSEVB-LH5 Bare evaluation board, as well as shuntless, galvanically isolated analog voltage output from the MIKROE-6632 compact add-on board, engineers can obtain precise measurements when evaluating these sensors.

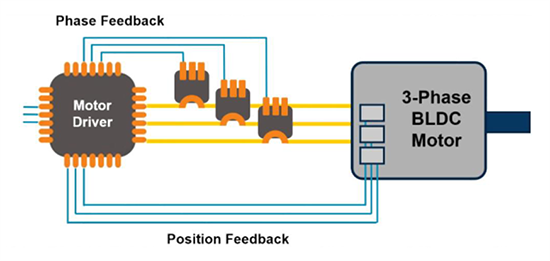

Capable of bidirectional current sensing up to 30A and delivering a fast 150kHz analog output, these sensors are ideal for demanding applications such as motor control, battery management, and power supplies. For motor drivers that act as the control center for power systems, these sensors provide a phase feedback loop to monitor the motor windings’ current precisely (Figure 1). Housed in a compact SOT23-W package, they offer a space-saving, UL-certified solution tailored for high-efficiency, high-voltage systems.

Figure 1: ACS3704x magnetic current sensors can play a key role in controlling a 3-phase BLDC motor with their galvanic isolation and high bandwidth. (Source: Mouser Electronics)

Tuesday’s Takeaway

Allegro’s ACS3704x magnetic current sensors are more than just a component—they’re a strategic upgrade for engineers looking to build smarter, safer, and more efficient systems. Whether you're designing the next generation of motor drives or optimizing an existing setup, these sensors deliver the performance and protection needed for modern applications.