Augmented Reality Hardware: Key to HMI

Time magazine and ABI Research called Augmented Reality (AR) the future of technology. Why? Because it is the nexus where the digital and physical worlds collide, and it creates game-changing opportunities for industries ranging from manufacturing to energy to healthcare. The notion of AR has been around for many years, fascinating hobbyists and technology enthusiasts with its ability to overlay text and images on real-world objects. However, in 2016, the smartphone game Pokémon Go thrust AR into the mainstream while showing the world how AR devices could extend themselves into a tool for the futuristic industrial worker.

Designing AR devices poses several hardware challenges. This article shows how AR can transform industrial environments— like construction sites and factory floors— and explores ways to overcome challenges in designing viable AR products.

The 21st Century Industrial Worker

The idea of empowering industrial workers in the workplace as well as in the field by superimposing digital information onto physical objects is very powerful and is poised to revolutionize many industries. For example, AR has the potential to reinvigorate the manufacturing sector by connecting workers with equipment and allowing them to interact with sensor data. This enables factory workers to automate guidelines or standards and see specific instructional content in real-time (Figure 1).

Figure 1: Augmented reality is transforming industrial workplaces by superimposing digital information onto physical objects. (Source: Intel)

Using AR technology to receive and view relevant content in real-time transforms how tasks are performed. The following examples illustrate how this technology can deliver relevant task-related information in many scenarios:

- A factory worker can receive step-by-step instructions on how to assemble a product while on the factory floor.

- An industrial designer can show side-by-side comparisons of new and old product designs, thus eliminating the need to create expensive, display-only prototypes.

- Field personnel can draw help from experts at remote locations via markings, messages, and diagrams made available on a glass screen while they are fixing equipment.

- A technician using AR wearable devices can manage pump station operations without going back and forth to a computer console.

- New employees and DIY-ers can identify problems and perform repairs by following step-by-step instructions using AR overlays.

- Car owners can diagnose and make repairs using an AR manual. In 2015, Hyundai launched an AR car manual. This app—available on smartphones and tablets—allows car owners to scan various parts of their vehicle and perform repairs using 3D overlay images and how-to videos.

These are only a few ways that AR can support a more mobile work environment while taking pressure off experts at central locations.

Designing the Human-Machine Interface

The Human-Machine Interface (HMI) in AR overlays schematics and audio onto real objects in order to facilitate tasks such as:

- Motion tracking

- Pattern recognition

- Data visualization

AR hardware—encompassing cameras, sensors, displays, and connectors—is quickly refining itself and the human-machine interface it employs in designs serving industrial applications.

Unique AR Design Challenges

Designing AR interfaces poses unique challenges. To begin, Application Programming Interfaces (APIs) and the apps ecosystem are still evolving, and the limited field-of-view in helmets, headsets, and displays pose unique challenges in hardware selection:

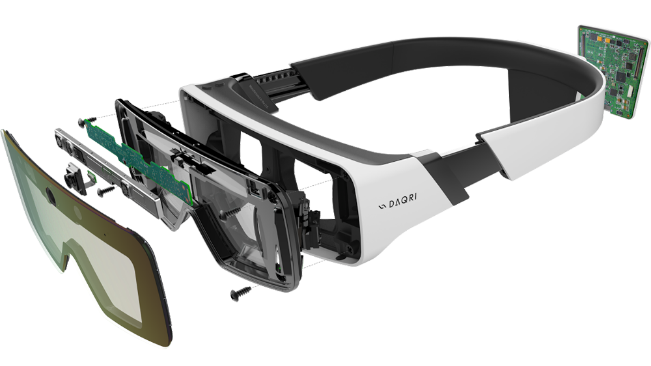

- Displays demand thinner and lighter components to meet industrial design requirements (Figure 2).

- Power delivery must be efficient to prevent data overloads and device breakdown.

- Components—like cameras, sensors, and displays—must accommodate ultra-high-speed streaming of graphics and video with near-zero latency.

- Connectors must be compact, light, fast, and reliable.

Figure 2: AR devices like DAQRI's Smart Glasses™ demand thinner and lighter components to meet industrial design requirements. (Source: DAQRI)

Unique Requirements For Connectors In AR Devices

Connectors are especially important in AR hardware designs. In general, they need to be compact, light, and fast; AR designs demand miniaturized connectors to replace bulky interconnect solutions with limited pin counts. And these connectors should be reliable enough to ensure signal integrity while serving AR applications that employ high-speed data links.

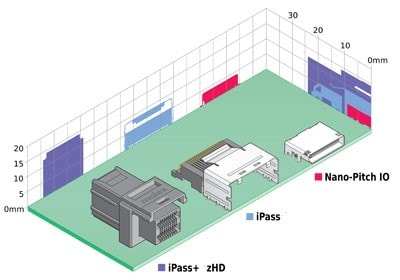

Furthermore, connectors in AR designs are required to meet the rising data transfer needs along with increased port density, and they should be able to provide multiprotocol support in order to facilitate a multitude of technologies. The Nano-Pitch I/O interconnect system from Molex boasts enhanced data speed and signal integrity in increasingly compact form factors. Moreover, it offers a flexible pinout that is optimized for high-speed applications. It also maximizes the number of high-speed lanes within the available cable lengths. These connectors measure 5mm × 23mm × 9mm and feature a 12mm mated connector-to-cable assembly height for right-angle cable exit (Figure 3). That makes them highly suitable for AR devices such as headsets and glasses.

Figure 3: Connector miniaturization is essential for cramming more circuitry into ultra-compact AR designs. (Source: Molex)

The highly compact AR devices also mandate connectors provide optimal routing for high-speed trace connections in order to shrink the PCB real estate. Molex's Nano-Pitch I/O connectors ensure design flexibility with vertical and bulkhead PCB configurations.

Power supply connectors are robust enough to transport power for video subsystems like the stereo camera. Power connectors in small form factors typically face the dilemma of choosing between headers that expose terminals to external damages and fully isolated headers that take up too much space.

Nano-Fit power connectors from Molex address this design challenge with a fully isolated terminal design that keeps the pitch package to a mere 2.5mm. Moreover, to simplify assembly on a PCB with multiple headers of the same circuit size, these power connectors offer keying options that facilitate proper mating and Terminal Position Assurance (TPA) to eliminate the risk of terminal backout.

Conclusion

ABI Research expects AR for enterprise applications to hit an inflection point in 2018. AR designers are quickly overcoming the hardware challenges, and the technology as a whole is gaining traction a lot faster than many industry watchers may have thought possible. AR device design requires a number of hardware considerations, especially for connectors. Pokémon Go showed the world how AR could engage people. Now it’s our turn to create AR devices for use in other industries and bring the potential of AR to the masses.