Goodbye, QWERTY: Touchscreens Dominate Smart Home's User Interface

It wasn't that long ago those "fear-factor" pundits were predicting that there would be an "epidemic" of carpal tunnel syndrome (yes, that was the word which was used!) due to our excessive, non-stop use of the venerable QWERTY keyboard. Oh, well, never mind: that hasn't happened—and it’s not because there is less need for a human-machine interface (HMI).

Instead, there are alternatives, and the QWERTY keyboard's role in consumer products is fading fast as other interfaces replace it. One approach is to use a custom-configured set of dedicated-function touch keys with a single plastic overlay to keep everything clean and washable, such as used on many microwave ovens. Another approach uses the now-common touchscreen interface, which is increasingly getting design-in consideration in many new applications. Source: © Lucadp | Dreamstime.com - Concept Of Home Automation Photo

There are two reasons for the trend towards touchscreens. First, costs have come down, due to high volume and technical advances, both driven by smartphone and auto-console use. Second, flexibility, as the screen's displays can be dynamically reconfigured to show different soft buttons at each step of the user-entry process. This allows much more freedom in initial design as well as user-friendliness in interaction. Further, users have become very comfortable with touch screens, using them in tablet PC, ATMs, gas pumps, and more, so it makes sense to see them in home automation devices from security-system control panels, to smart climate-control interfaces and even to integrated smart-home controllers, Figure 1.

Figure 1: The long-predicted smart home with a full range of sensors and controllers is now becoming a reality due to advances along many dimensions; even systems which support remote smartphone-based control rely on a dedicated control panel for in-house use and setup.

User interfaces are not limited to touchscreen techniques, of course. Some vendors are investigating other techniques, such as user voice-commands and gestures/haptics. So far, these have not provided the sufficient functionality, consistency, benefits, or cost advantages to justify being used in mass-market home applications. They may, however, have advantages in special circumstances such as for use by people with specific disabilities.

Go Resistive or Capacitive?

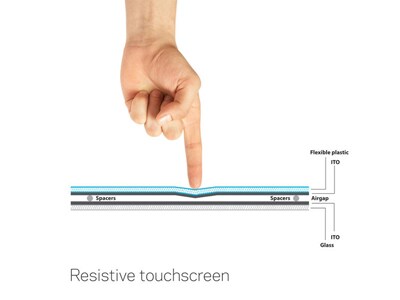

Touch screens can use either resistive or capacitive technology. In brief, resistive sensing uses a thin, flexible, conductive-yet-transparent top layer of plastic separated from a conductive glass layer (see Figure 2.) As the user presses on this layer, physical contact occurs between the conductive surfaces, and this resistance path is measured by the touchscreen controller along both the X-axis and Y-axis to determine where the press occurred.

Figure 2: The resistive touchscreen uses a pair of conductive transparent layers; pushing the flexible top one completes a path between layers and the resultant resistance can be measured to determine the location of the finger contact.

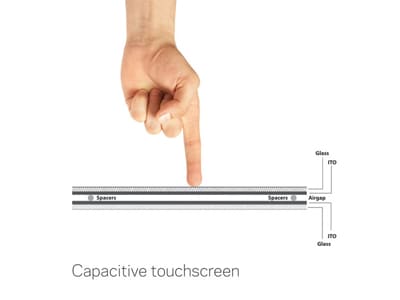

The capacitive touchscreen also consists of two separated conductive layers, but both layers are of non-flexible glass; in one variation, the lower one is coated with a conductive set of gridlines (see Figure 3). When the user's finger touches the glass of the capacitive surface, this distorts the local electrostatic field due to the capacitive nature of the fingers (the body is a conductor of electrical charges). The touchscreen controller monitors the distortion-induced changes in capacitance, again in both X and Y directions, to determine where the finger had touched the screen.

Figure 3: In the capacitive touchscreen approach, the finger's proximity distorts the electric field formed by an insulating layer and a conductive layer.

Each approach offers tradeoffs in performance, user experience, and cost, depending on requirements. In general, capacitive technology is more cost-effective for smaller and medium-size screens (up to about 10 inches) as its cost increases sharply with size. It supports multi-finger operation and advanced gestures plus zoom in/out, but these are generally not needed for the home-automation or smart-appliance user experience (note that some resistive controller techniques do support simple gestures and multi-touch use).

Compared to resistive displays, the capacitive display tends to be brighter due to fewer layers between the underlying image source and the top layer; again, this is not critical in most home situations, which are generally well-lit. Capacitive touchscreens have a thicker, scratch-resistant top layer of glass rather than the thinner one of resistive screens which must bend with finger pressure, and so are more rugged.

Finally, the power requirements of capacitive units are lower for a given size than the resistive technology. While lower power is always a positive attribute, in the case of home-automation systems with a nearby AC source, or where the touchscreen is part of a larger appliance, this is not as compelling a benefit as it would be for a handheld unit used in the field. For most home-automation controller and appliance designs, resistive touchscreens are the preferred choice for the foreseeable future due to technical attributes and cost advantage.

It's important to keep in mind the implications of the predefined, limited-function needs of home applications. Unlike a smartphone, where the user’s touchscreen interface must deal with the randomness and uncertainty of disparate types of web pages, emails, video, and more, the human-machine interface (HMI) for an appliance or home controller is more constrained. It needs to support only a limited set of features, functions, and user softkeys, all of which can be defined in advance. This means that the more complex touchscreen solution with extra capabilities is not needed with extra features such as zoom or finger drag.

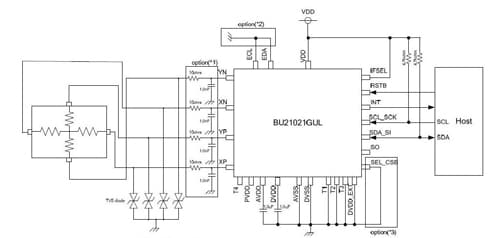

Figure 4: Within the ROHM BU21021GUL resistive touchscreen controller is a dedicated processor with embedded algorithms for noise filtering, touch assessment, and more, to off-load the system processor from these specialized burdensome tasks.

The ROHM BU21021GUL touchscreen controller is representative of resistive interfaces (see Figure 4). This chip works with widely available legacy-type 4-wire resistive touchscreens, and is capable of detecting X/Y coordinates, including touch pressure in one-point detection mode and a pair of X/Y coordinates in two-point detection mode. It includes a dedicated, embedded CPU for noise filtering, coordinate calculation, and gesture detection, thus relieving the system processor of the task (and associated coding/debugging).

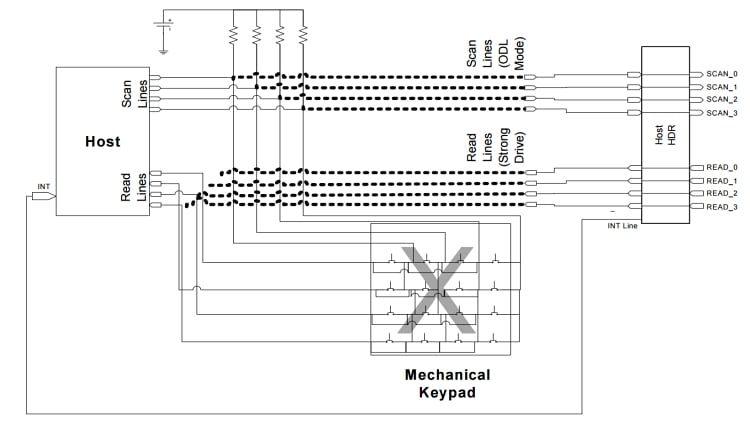

For the many home-automation and appliance applications do not need the full functionality that a touchscreen can provide, their user-interface needs can be met with a matrix of touch-sensitive buttons. This reduces BOM cost, reduces the number of physical connections, and presents a sealed surface for greater reliability compared to discrete mechanical switches. For these designs, Cypress Semiconductor offers the CY8CMBR2016 CapSense Express 16 Button Matrix Controller to easily incorporate a capacitive touch-based user panel (see Figure 5). It is a hardware-configurable IC and does not require any software tools, firmware coding or device programming.

Figure 5: The Cypress Semiconductor CY8CMBR2016 CapSense Express 16 Button Matrix Controller is designed to allow an easy upgrade path from discrete electromechanical switches to sealed capacitive switches, and is well-suited where limited functionality is required, such as a microwave oven or dishwasher.

The Cypress CapSense Controller includes Cypress's SmartSense auto-tuning algorithm, which eliminates the need to manually "tune" its response and compensate for the unavoidable capacitive variations of the buttons and associated printed-circuit board. This yields savings in both development and production cycles. The device supports up to 16 capacitive touch buttons that can be physically laid out in any format, including as a linear or matrix array. With its backward-compatible key-scan interface, designers can use it to replace mechanical switches or quickly upgrade and retrofit existing keypad-style applications in fire-alarm control panels, security systems, and even door locks.

Wired or Wireless HMI Connectivity?

A user interface needs to be connected into the larger system to be useful, of course. This can be done via a proprietary hardwired link, a standard hardwired interface such as a USB port, or a wireless connection. The decision is largely driven by the usual factors of application, location, and how the user interacts with the interface, as well as cost and physical-compatibility issues.

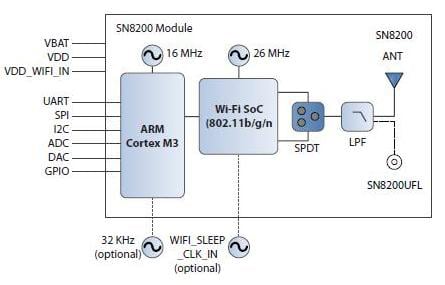

In many cases, a wireless connection is not only preferred, but mandatory. For example, a smart-home control panel/user interface located in the house entryway interacts with the house-wide wireless system. Its connection to that system controller needs to be wireless itself, since running networking cables within the wall is a costly and an installation headache. Further, this control panel may need to support multiple standard protocols such as Bluetooth, Wi-Fi, and vendor-defined proprietary protocols. For a Wi-Fi interface, the SN820X series of Wi-Fi network controller modules from Murata Electronics, (Figure 6) comprises a family of small (20 × 30 × 2.8 mm), low-power, self-contained units that provide simple serial-to-network connectivity to the Internet (2.4GHz IEEE 802.11b/g/n).

These modules incorporate the “Wireless Internet Connectivity for Embedded Devices” (WICED) architecture from Broadcom Corporation and host a Wi-Fi, TCP/IP network stack, security firmware, and other network-application features. For development, the modules also support Murata's Simple Network Interface Connection (SNIC) software and EZ Web Wizzard™ software.

Figure 6: For drop-in serial-to-Wi-Fi connectivity, the SN820X series of network controller modules from Murata Electronics in includes all necessary functions and I/O in a 20 × 30 × 2.8 mm board-mountable module.

Some user-control panels may also need to provide the wireless interface to specialized external points such as alarm-system nodes (doors, windows, and thermal sensors, to cite a few). These wireless connections may use protocols or frequencies which are not associated with Wi-Fi, Zigbee, or Bluetooth in order to save power and reduce cost, or maintain a proprietary market position. For example, many of the sensors for home automation, smart buildings, or alarms use RF frequencies below 1 GHz.

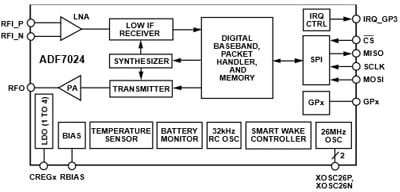

For these situations, ICs such as the ADF7024 low-power, sub-GHz transceiver from Analog Devices are possible candidates (Figure 7). This 5 × 5 mm transceiver supports operation in the 431 MHz to 435 MHz and 862 MHz to 928 MHz bands, for two-level frequency (FSK) and Gaussian frequency (GFSK) shift keying modulation, at modest data rates of 9.6 to 300 kbps. Since this component is primarily intended for remote sensors powered by batteries or energy-harvesting sources and located throughout a home or office, low-power operation is a must-have, especially during long quiescent periods which are inherent in these situations.

Figure 7: Operating below 1 GHz, Analog Devices' ADF7024 low-power transceiver is a 5 × 5 mm IC for the 431 MHz to 435 MHz and 862 MHz to 928 MHz unlicensed (but still subject to regulation) ISM bands, and is a good fit with widely scattered local sensors in smart homes and buildings.

To meet these requirements, the ADF7024 features multiple sleep modes, including a deep-sleep mode where current consumption drops to 0.33μA; a sleep mode where the internal 32-kHz oscillator is active with slightly higher current draw of 0.75μA; and an autonomous receiver "sniff and smart-wake" mode where it looks to sense and receive packets at up to 300 kbps, requiring just 11.75μA. Note that even if the wireless transceiver does not have to meet the technical requirements established by standards such Wi-Fi, Zigbee, or Bluetooth, it must still meet various regulatory mandates for unlicensed operation. The ADF7024 meets both U.S. FCC Part 15 (Parts 15.231, 15.247, and 15.249) as well as the European ETSI EN 300 220 requirements.

While advances in wireless connectivity and associated mobility have been receiving so much attention , its inherent attributes and natural characteristics mean that it may not be the right choice for situations such as connecting the user's touchscreen to the appliance. Among the reasons are cost, unnecessary complexity, issues of sensitivity to EMI/RFI (appliances are major noise source, especially if they have motors and turn on/off transients), possible channel interference from nearby wireless devices in the band, and issues of protocol and set-up.

If the control panel is physically an integral part of the appliance such as in a dishwasher (even if the appliance is smart/IoT and has Internet connectivity), then a wireless internal link may be a solution with potential design headaches, higher cost, and consistent performance issues. The engineering reality is that using a short piece of wire or cable as the interconnection medium is often the simplest, most direct way to achieve high performance, low cost, and reliable operation.

Using a standard USB interface as an interconnection offers some product design advantages. There are many development tools that allow the user panel to be programmed and debugged separately from, and in parallel with, the rest of the product development. Using a standard port also modularizes the product family, making it easier to offer a range of appliance user interfaces. Thus, a single user-panel hardware implementation can be adapted to match various appliances in a family, but with different screen interaction and soft keys as needed.

Also, a standard USB interface allows field-service personnel to disconnect the factory-supplied user panel, and then connect a laptop PC with advanced diagnostics. This capability makes it easier to upgrade the appliance's firmware in the field when a problem (aka bug) is found in original operating firmware. The possibility of needing such upgrades is an increasingly worrisome issue, as even basic appliances are loaded with sophisticated, software-based features. Field fixes must be completed even when the appliance installation does not have available Internet connectivity for downloading the revised firmware; thus physical connectivity via USB port and a service rep visit is the alternative.

However, the basic USB connector may not be rugged enough for an appliance such as a dishwasher or refrigerator. Even though the home itself is a fairly benign environment in many ways, the connector's actual environment can be harsh with vibration, moisture, dirt, and other degrading conditions. This is often the case when the connector is located where drainage and airflow are inadequate.

That’s where a USB connector such as the IP68 waterproof micro-USB 2.0 connector from TE Connectivity has a role (Figure 8). With a metal injection molded (MIM) shell, this female connector provides protection against damage caused by underwater submersion and dust. With undercuts in its design which match the standard plug latches, the connector keeps the plug mated like the conventional micro-USB connector. Further, its metal reinforcement plate prevents damage to the plastic tab which contains the contacts inside the connector, and helps prevent electrical short circuits, which often appear as frustrating intermittent failures. The screw-type mounting ears make it easier to integrate and position the connector in the final application. This mounting yields better mechanical integrity than relying on wire leads and through-hole circuit-board mounting, or attachment via surface-mound bumps and PC-board lands.

Figure 8: Connectors often don't get the consideration they need until late in the design cycle, but this ruggedized micro-USB 2.0 female connector from TE Connectivity provides interconnect and mounting integrity needed in unintentionally harsh appliance installations.

Regardless of user interface, advances in integration and functionality make it more practical and convenient to combine the touch display, individual touch switches if needed, along with the actual control electronics. This simplifies packaging and interconnect issues between the part of the design which is visible to the user and the circuitry which the user does not see. Rather than have separate circuit boards or multiple enclosures, the interface electronics for the display and front panel can be a single circuit board, and the operation electronics for the system as well, where it makes sense for the application and installation.

Even when the user interface panel is physically separated from the remaining electronics, as is often done with high-power motor controls and the high-voltage electronics of a dishwasher or refrigerator, designers now have much more flexibility in configuration and packaging. Of course, it's a continual back-and-forth situation, as they are also expected to add additional functions and features, which in turn requires more of the newfound flexibility.