Optical Measurement Guidelines

Featured Products

Resources

Introduction

The LED industry is growing rapidly and this naturally brings up an important need for reliable measurements of LEDs and solid state lighting (SSL) products. These measurements often form the foundation for a fair comparison between SSL products from different vendors. Consequently, there is an industry-wide push for standards that ensure accurate and repeatable measurements of optical properties for LEDs and SSL products. The CIE 27:2007 report from the International Commission on Illumination covers guidelines on how photometric, radiometric, and colorimetric quantities for individual LEDs should be measured in calibration labs. However, the report defers responsibility to manufacturers of LEDs and SSL products to ensure that their equipment measure the optical properties of their products correctly. The optical performance of LEDs and SSL products can be measured with an integrating sphere. However, standard integrating sphere calibration procedures are not always adequate to accurately measure the optical properties of LEDs due to the high spectral radiant flux in the blue region. The objective of this paper is to introduce appropriate calibration procedures, as well as practical operating guidelines for integrating spheres which are used for the characterization of LEDs and SSL products.

Optical Measurement Basics

The spectral radiant flux distribution of a light source describes how much radiometric power is emitted by the light source per unit of wavelength across the electromagnetic spectrum. Knowledge of the spectral radiant flux distribution of a light source allows the user to derive other useful optical properties for the light source, including total luminous flux, x-y chromaticity coordinates, dominant wavelength, purity, Correlated Color Temperature (CCT), Color Rendering Index (CRI), peak wavelength, centroid wavelength, and full width at half maximum (FWHM). A list of several common engineering terms, which are regularly used to refer to certain optical quantities derived from the spectral radiant flux distribution, can be found in Appendix A.

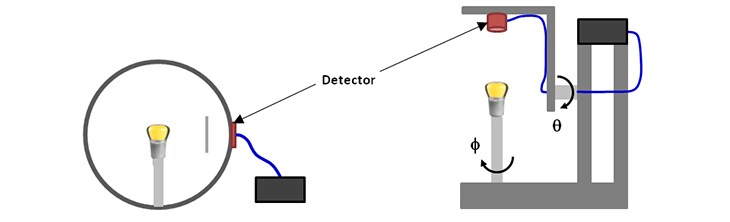

Two different measurement tools are typically used to measure the spectral radiant flux distribution of a light source (see Figure 1):

- An integrating sphere collects all the lights from a light source placed inside the sphere.

- A goniometer measures the spectral radiant flux distribution of a light source from many different angles around the source and integrates the results to yield a combined spectral radiant flux distribution for the light source.

Figure 1. An integrating sphere (left) or a goniometer (right) are typically used to measure the optical performance of an LED or SSL product.

Due to its ease of use, an integrating sphere is often preferred over a goniometer to measure the performance of individual LEDs and SSL products (see Appendix B for a detailed comparison). Therefore, the remainder of this paper discusses recommendations and practical guidelines for optical measurements with an integrating sphere.

Integrating Sphere Measurements and Calibration

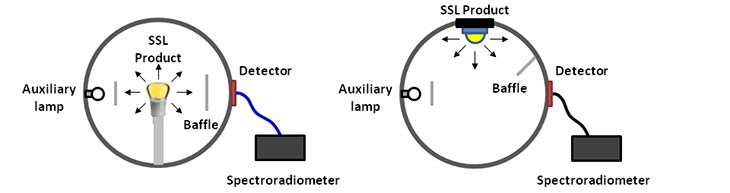

There are two different integrating sphere configurations that are typically used to characterize the optical performance of LEDs and SSL products, see Figure 2. A 4p configuration (left) is best suited for an omnidirectional light source while a 2p configuration (right) is best suited for a forward emitting light source.

A complete integrating sphere test system consists of:

- An integrating sphere with appropriate ports and baffles

- Reference calibration standards (spectral lamp, reference LED), calibrated by an ISO/IEC 17025 certified laboratory, and appropriate power supplies

- A temperature controlled socket may be required for LED standards to ensure consistent results

- Spectroradiometer

- Auxiliary lamp and power supply

- Computer plus software for calibration and measurement

Integrating spheres can be used to characterize a variety of light sources, including LEDs and SSL products. However, in order to obtain accurate measurement results for LEDs, certain calibration procedures and best practices, as outlined in the remainder of this section, should be followed. In particular, the standard calibration process for an integrating sphere must be tailored to LEDs in order to properly account for their high spectral radiant flux in the blue region.

Figure 2. Typical integrating spheres configurations for optical measurements: an omnidirectional 4p configuration (left) and a forward emitting 2p configuration (right).