The Modern Distributed Power Architecture

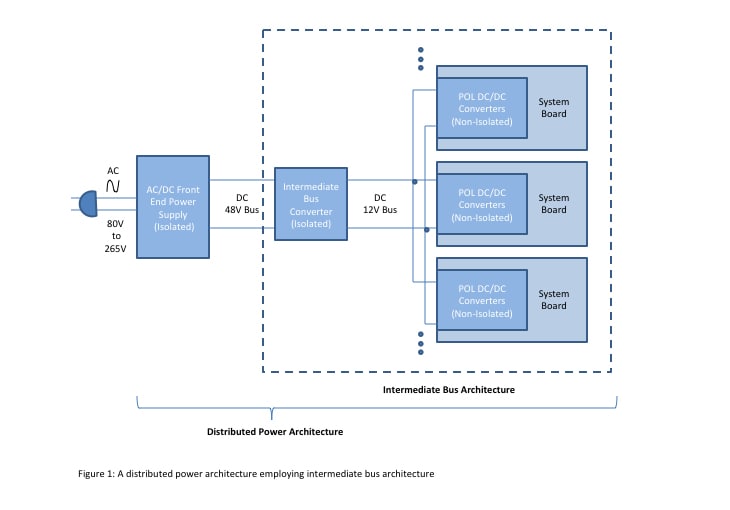

How do you get power from the wall or main power supply to the load in contemporary telecom, data communications, medical and industrial applications? There was a time when the predominant power supply architecture consisted of a centralized power unit that distributed power throughout the system via a network of cables and supply bus bars, but as power demands have changed, so have system power topologies. Driven by increasing power consumption, increasingly lower voltage level requirements of semiconductor devices, and a need for better supply performance to support digital processing technologies, in conjunction with the availability of advanced products from power electronics manufacturers, more sophisticated power distribution architectures are being implemented today. The modern distributed power architecture (DPA) can spread the concentration of heat throughout the system, support high currents at very low voltages, and provide excellent transient response to rapidly changing loads. Additional advantages include the flexibility to add voltages or current requirements, and the ability to continue system operation when one point of load fails. With overall goals of cost effectiveness, minimal size, and high efficiency in mind, today's superior DPA can be broken into three main areas of consideration (Figure 1) — the AC/DC front end power supply, the point-of-load dc/dc converters, and the intermediate bus architecture (IBA) often found in between. Let's have a closer look at the functionality of each area and investigate some of the products available to support designers.

AC/DC Front End Power Supply

In the era of Thomas Edison, Nicola Tesla, and George Westinghouse, the argument over AC versus DC for utility transmission and distribution was decided and AC won out due to lower transmission losses over long distances. Today's electronics are primarily DC-driven however, and thus the need to transform the typically 80 to 265-V, 50- or 60-Hz AC single-phase waveform that is supplied at the wall into a useful DC source. The concept of front end AC/DC conversion itself is rather straightforward; You can accomplish this by using a transformer to step the high-voltage AC line power down to a more manageable voltage, running the low-voltage sinusoidal AC (0 VDC value) though a bridge rectifier to produce a standing waveform with a DC voltage value equal to the AC amplitude, and adding a large capacitor to smooth out the voltage. The smoothed voltage is then passed through a DC/DC converter to achieve a steady DC bus voltage for the system. Typical output voltages of AC/DC front ends are 48 V for telecom systems, 12V and 24 V for datacom servers, and even 400 V DC (from a 3-phase 400-V AC input available in parts of Europe) for some datacom and medical equipment.

The challenge in AC to DC conversion today stems from the need for power factor correction (PFC) and harmonic filtering. The power factor for a given AC/DC power supply quantifies how much real, useable power it ultimately delivers to the load versus how much apparent power is being supplied by the power grid. It is a measure of wasted power. It is also a measure of harmonic distortion, which is largely introduced when the AC input current waveform becomes out-of-phase and non-sinusoidal compared to the AC input voltage waveform during the process of rectification and smoothing. Disadvantages of low power factor (a unity power factor is ideal) include the power utility companies— inability to charge for reactive (non-real) power consumed, the possibility of harmonics injecting back into the grid causing service disruption, and the safety hazard that is posed by equipment subject to vibrations due to said harmonics. Consequently, PFC and harmonic filtering have moved beyond being simply good design practices, but into the realm of standards and regulations such as EN/IEC61000-3-2 for products consuming more than 75 W. Internationally, new power regulations increasingly call for power factors of .9 or higher, as well as limitations on total harmonic distortion. The simplest PFC method typically involves adding a capacitive filter at the AC input, though it is difficult to achieve a PFC of much higher than 0.7 this way and it applies better to constant loads. Today's more stringent PFC requirements, including the need to support rapid and high load changes from modern semiconductors typically mean the use of active PFC through implementation of a boost-converter circuit between the bridge rectifier and the smoothing capacitor.

At the same time that PFC requirements are increasing, so are tighter efficiency standards, even though PFC decreases efficiency. A number of new application-specific regulatory standards dictate high power supply efficiency across the entire load range, from full load to as low as 10% load. Combine the need to keep up with evolving regulations with the ongoing pressure to deliver more wattage per cubic inch at competitive costs, and today's system power designers have reason to look for an easy solution. Fortunately, complete AC/DC front end power supply modules are available to simplify the front-end design for a DPA, as seen in Table 1. These products all offer active PFC, high efficiency over the load range, high power density, as well as overvoltage, overcurrent, and thermal protection. In addition, some models offer advanced features such as hot-swap capability, active load sharing for N+1 redundancy, paralleling for easy scalability, and on-board microprocessors with I2C, PMBus, or Ethernet interfaces to enable real-time monitoring and dynamic digital optimization based on load levels or other set parameters.

| Manufacturer | Product | Output Power | Efficiency @230 Vin | Output Voltage (V) | Power Factor | Form Factor | Features |

| Artesyn Embedded Technologies | HPS3000 | 3000W | 82% at 10% load 90% at full load | 48 | 0.97 typ Meets EN61000-3-2 | 1Ux3U | Hot Swap, N+1 redundant, PMBus, digital technology, parallel 4x =12KW, PoE |

| Cincon | CBM100S | 100W | 75-80% at 10% load, 90-91.5% at full load | 12, 24, 28, 36, 48 | Meets EN61000-3-2 | Encapsulated, board mount, full brick | Baseplate cooled (no fan required), 17mm low profile, <0.5 W at no load |

| GE Critical Power | CAR1248 | 1200W | 91% at full load | 48 | 0.99 typical, Meets IEC555, EN60555-2, EN61000-3-2 | 1Ux2U | single-wire active current sharing; remote on/off, remote sense and control circuits, I2C |

| Mean Well | RSP-150 | 150W | 81.5% -90% | 3.3, 5, 7.5, 12, 13.5, 15, 24, 27, 48 | 0.93, full load @230 Vin | 1U | Convection cooling, 30mm low profile, remote on/off |

| Murata | D1I86G | 460W | 83% at 10% load, 92% at 50% load, 88% at full load | 12 | 0.99, full load @230 Vin | 1U | Includes standby 12 V output, Hot Swap, N+1, paralleling with droop current sharing, internal fan, PMBus |

| Murata | MVAC250 | 250W | 82% at 10% load, 94% at full load | 12, 24, 50 | 0.96, full load @230 Vin | 1U | 3rd edition medical approval, Convection cooling, Isolated 12V fan output, Isolated 5V standby output, Current sharing options |

| Bel Power Solutions | ABC/MBC450 | 450W | 90% (24V, 48V, 30V), 86% (12V, 15V), 83% (5V) at full load | 5, 12, 15, 24, 30, 48 | 0.95 @230 Vin | Open Frame, 3"x5" | MBC=3rd edition medical approval and high isolation |

| TDK-Lambda | HFE | 1600W, 2500W | 90-93% at 75% load | 12, 24, 48 | 0.98, full load @230 Vin | 1U | parallel 5x =7600W, MU for remote program via I2C and PMBus, load shedding |

Intermediate Bus Architecture (IBA)

IBA is basically a multi-stage DPA in that it inserts another level of power distribution between the front-end power supply and the POL converters. It evolved over the last decade from efforts to improve efficiency while saving cost and space in DPA. Whereas a traditional telecom DPA might have distributed a -48V backplane voltage to each shelf/ array of line cards each with on-board isolated DC/DC modules to support all the voltages required by the load, an IBA replaces the multiple isolated DC/DC modules with a single intermediate bus converter (IBC) that is used in conjunction with non-isolated point-of-load converters (niPOLs). The job of the IBC is to provide an optimal intermediate-bus voltage, such as 12 V from the 48 V distribution bus, as well as electrical isolation.

Though IBA is popular, not all applications benefit from it, and thus a careful power system evaluation should be performed to determine the best power distribution architecture. Overall efficiency can be lowered due to the three conversion stages and the cost/space trade-off of using IBCs versus isolated POL modules must be analyzed. In addition, widespread adoption of synchronous rectification has enabled low voltage outputs such as 3.3 V, 5 V, and 12 V from AC/DC front ends that are as efficient as higher voltages (See Table 1), thus eliminating the need for an intermediate bus. Distribution of higher voltages such as 48 Vat lower currents does reduce the need for heavy copper traces/bus bars and specialty high-current connectors though, thus providing a cost and space savings in that respect compared to distribution of lower voltages at higher currents to achieve the same power.

When selecting an IBC, look for an isolated step-down DC/DC converter that delivers the specified output voltage over the full range of the nominal distribution bus input. In the Texas Instruments white paper, "Improving System Efficiency with a New Intermediate-Bus Architecture" by Rais Miftakhutdinov, he also lists the following requirements and parameters to consider, with the most important targets being high efficiency and high power density at low cost:

- Efficiency: 96 to 97% typical

- Power density: >250 W/in3

- Cost: $0.10 to $0.20 per watt

- Input-voltage range:

- 43 to 53 V for servers and storage

- 38 to 55 V for enterprise systems

- 36 to 60 V for narrow telecom range

- 36 to 75 V for wide telecom range

- 380 to 420 V for medical and data-center high-voltage systems

- Power range: 150 to 600 W and higher

- Most popular transfer ratios: 4:1, 5:1, and 6:1 for 48-V nominal input voltage

- Mechanical form factor:

- 1/4 brick for > 240 W of output power

- 1/8 or even 1/16 brick for < 240 W of output power

- Switching frequency: Relatively low at 100 to 200 kHz

- Most popular power-stage topologies: Full-bridge, half-bridge, and push-pull

- Secondary-side rectification: Almost entirely uses synchronous-MOSFET, self- or control-driven rectifiers

- Control approaches: Fully regulated, semi-regulated, or unregulated

IBCs can be differentiated by the three types of control (fully regulated, semi-regulated, or unregulated) just mentioned.

The fully regulated IBC maintains a constant output voltage over a broad range of line and load conditions. It is most often used for its ability to handle a wide input voltage range when the distribution bus is not anticipated to be well regulated. For a nominal 48-V input, the fully regulated IBC might specify 36 to 75 V as the min/max input range. Limitations include the lowest efficiency (93% typical), lowest power density, and highest cost of the three control types.

Fully-regulated IBCs are readily available, including Flex Power Modules' BMR456 and BMR457 series which were awarded the 2012 Product of the Year by Electronic Products Magazine. The intelligent products make use of firmware and control via PMBus for power consumption reduction and can reduce board power consumption by 3 to 10%, depending on the application. The quarter-brick BMR456 output voltage can be adjusted within an operation range of 13.0 V to 8.2 V. The eighth-brick BMR457 delivers 13.2 V to 8.2 V, adjustable down to 6.9 V.

The semi-regulated IBC supports the same wide input range as the fully regulated IBC, but its output is not regulated over the entire input voltage range. Though efficiency is improved over a fully-regulated IBC (95% typical), it is not as efficient or as low cost as an unregulated control approach.

The final type of IBC provides an unregulated output voltage that changes with a fixed ratio to the input voltage. For example a 4:1 fixed ratio IBC will generate a 9 V to 15 V output, provided the input voltage range is narrowed to 36 to 60 V. This type of IBC offers the highest efficiency (97% typical), highest power density, and lowest cost.

Recent industry-wide intellectual property issues concerning the use of semi-regulated and unregulated IBCs in IBA have greatly limited the availability and use of these types of IBC. The Texas Instruments UCC28230EVM based on the UCC28230 Advanced PWM Controller is one of a few related products still available. The evaluation module demonstrates a 300-W, 96%-efficient unregulated bus converter design that outputs a nominal 9.6 V with a 43-V to 53-V input voltage range.

Non-Isolated Point-of-Load (niPOL) DC/DC Converters

With basic isolation provided by the AC/DC front end and full isolation provided by the IBC in an IBA, small and cost-effective niPOLs can be used to power the load. These DC/DC converters need to handle the trends towards increasingly lower POL voltages and sharply-rising currents drawn by modern DSPs, FPGAs, and ASICs, amid demands for tighter regulation and lower noise performance. Luckily a plethora of great choices are available to board designers in the forms of linear regulators, switching regulators, and even products that combine the two.

When possible, choose linear regulators to directly power the signal conditioning and signal processing components. All voltage regulators produce noise, but the linear regulator inherently produces less compared to its dc-dc conversion cousin, the switching regulator. Linear regulators can also offer good power supply ripple rejection (PSRR). A high PSRR specification at the switching frequency of any switch mode power supply fed into the linear regulator input will help attenuate that switching noise so that it does not get introduced to the signal chain and cause interference issues. This technique is called post-regulation. Additional filtering may be required to dampen noise at high frequencies, as PSRR falls off eventually to 0-dB at higher frequencies.

The Texas Instruments TPS7A4700 low noise, 1-A low-dropout linear regulator supports a very wide input voltage range of 3 to 36 V, provides output voltages from 1.4 V to 20.5 V with ultralow-noise (4.17μVRMS) and high PSRR (80-dB @ 1kHz ). The device is ideal for powering operational amplifiers, analog-to-digital converters (ADCs), digital-to-analog converters (DACs), and other high-performance analog circuitry.

The downside of linear regulators is that they are not very efficient at power conversion, and thus can get hot. Calculate the power dissipation in the application using Pdiss=(Vin — Vout)*Iload , and compare the wattage against the thermal rating of the package. If it looks like there are going to be heat issues, opt for more thermally enhanced packages like QFN, or consider a switching converter instead. Generally speaking, this is the case if the load continuously draws much above 1A. However, there are 1.5-A, 2-A, and 3-A rated linear regulators commonly available.

Switching DC/DC converters offer higher efficiency than linear regulators as the difference between input and output voltage increases and as load current increases. There are several factors to consider when selecting a switcher. First, look for low output voltage ripple, say, less than 30 mVpp. Follow up the switcher with a linear regulator for post-regulation if a more quiet power supply is desired. Second, choose a high switching frequency to achieve a smaller package and better transient response, while avoiding the lower frequency bands where noise can be disruptive. Another desirable feature to consider is switching frequency synchronization. In a system with multiple converters, similar, but not matching switching frequencies can produce a disturbance called beat frequency phenomenon. The ability to synchronize the switching frequencies of the regulators prevents the formation of beat frequencies. In addition, it helps keep the EMI generated within the system to a predictable set of frequencies.

Also consider that today's designs are implementing FPGAs and DSPs that are pushing the limits of technology, with some unintended consequences. A given device may need power sequencing, soft-start, or power-good indication to operate properly. Modern power management solutions have these capabilities integrated. Table 2 lists a variety of switching dc/dc step-down converters with desirable features for niPOL.

| Supplier | Device | Vin (V) | Vout (min) (V) | Iout(A) | Output Voltage Ripple (mVpp) | Switching Frequency | Freq Synch | Power Seq | Soft Start | Power Good |

| Intersil | ISL8206M Power module | 1 to 20 | 0.6 | 6 | 8 | 600 kHz | No | No | Yes | No |

| On Semi | NCP1592 Switcher with integrated FETs | 3 to 6 | 0.891 | 6 | 10 | 280 kHz to 700 kHz | Yes | No | Yes | Yes |

| TI | TPS54620 Switcher with integrated FETs | 4.5 to 17 | 0.8 | 6 | 33 (per EVM) | 200 kHz to 1.6 MHz | Yes | Yes | Yes | Yes |

| TI | TPS84621 Power module | 2.95 to 14.5 | 0.6 | 6 | 30 | 250kHz to 780 kHz | Yes | Yes | Yes | Yes |

If board space is at a premium, consider the modern power management solutions that integrate the switching dc/dc converter and post-regulation linear regulator into a single, small package. One such example is the TPS54120 from TI. This device combines a high-efficiency switching dc/dc converter with a low-noise, high PSRR low-dropout linear regulator to support 1-A, noise-sensitive applications. The TPS54120 also includes switching frequency synchronization, soft-start, and power-good indication in a space-saving 3.5-mm x 5.5-mm thermally-enhanced QFN package.

Bringing It Together

The modern DPA has increased in complexity with many new factors to consider with respect to standards and regulations, intellectual propriety, and evolving trends. Mouser is committed to helping the designer by providing all the major building blocks for the stages of a DPA, as well as many of the passive and mechanical components that tie it all together.