Wearable Devices: Addressing the Need for Superior Power Management

Image Source: Maridav/shutterstock.com

By Mark Patrick, Mouser Electronics

The main design problems that engineers have to deal with in a wearable technology context are overall compactness and the power budget. The former will enable greater comfort for the wearer, while the latter will facilitate prolonged operation—both of which encourage greater usage. However, these features can have a detrimental effect on one another.

Although microelectronic components are decreasing in their physical dimensions, their level of complexity is constantly rising, so that new features and functionality can be offered. This consequently puts a strain on the available battery resources. Battery management technology employed must deliver rapid charging capabilities, enabling the wearable device to be powered for a sufficient number of hours to avoid frequent recharging, which would adversely affect user experience. This calls for innovation in respect to the constituent power management integrated circuits (PMICs).

Modern wearable devices allow the wearer to monitor a wide range of vital parameters. Depending on the particular objective of the device, some values are more important than others. The position of the device on the body significantly affects what can or cannot be measured. Generally, the most suitable position is the wrist, as it provides an optimal point for monitoring health/fitness-related parameters and also offers easy access for the wearer to check the captured data.

Clearly, the challenge is to find a way to support ultra-low-power operation while still achieving a compact form factor. Streamlined, lightweight designs will be the most appealing to consumers and witness greater commercial uptake. Therefore, Engineers must keep this in mind during the product development phase. Conversely, the construction of the wearable device limits the size of the battery and therefore its operational duration. One of the most common frustrations among consumers is products that do not have enough battery life.

Power Management Design: Efficient Energy Management

The dynamics of maintaining minimal power consumption levels in conjunction with batteries constrained by the product form factor are forcing design teams to make difficult circuit layout choices in order to obtain a fully optimized final product. The wearable device must be able to encompass different multimedia and sensing capabilities, along with having adequate battery resources, while not being too bulky. The generally used approach is to divide the design into analog and digital blocks according to the specific power needs and then look at optimizing them accordingly. Many circuit domains can be deactivated when not required, but others depend on continuous operation.

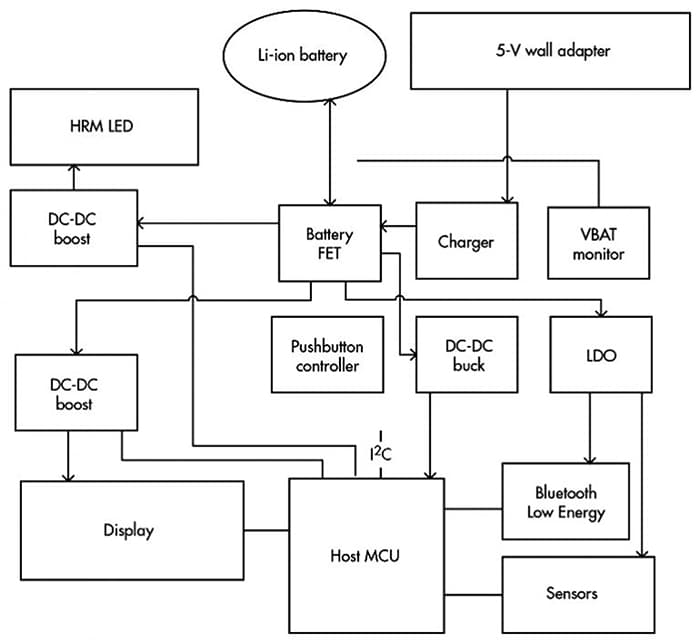

A typical wearable architecture will include the following elements: microcontroller, memory, small display, appropriate sensor mechanisms, communication ICs, and accompanying power management circuitry. The power management aspect will comprise a PMIC that takes care of charging, in addition to various buck converters and several low drop-out (LDO) voltage regulators to support the Bluetooth® and Wi-Fi® connection.

A wearable device's power management system will need to cover several voltage rails—one for the microcontroller, one for the display, and usually another for the sensors (see Figure 1). Microcontrollers and sensors spend most of their time in sleep mode but wake up to perform scheduled functions or respond to user input. Many wearable sensors work with voltages as low as 0.8V. If the load is very active (for example, a cardiac sensor that performs sampling once every few seconds), the current consumption of the microcontroller is normally estimated to be between 35μA and 40μA per MHz, thus making it a major focus when looking to uphold ultra-low-power design.

Figure 1: Typical circuit architecture of a wearable device. (Source: Renesas)

A power management system performs the DC/DC power conversion in two distinct forms:

- Via the linear regulators—which can be wholly integrated into the PMIC die and have voltage scalability.

- Via inductor-based switching regulators—which can be highly efficient and have voltage scalability, but tend to be discrete rather than integrated.

These regulators differ in terms of physical size, flexibility, efficiency, etc. Consequently, the following points should be taken into account when embarking on a wearable technology-based design project:

- Use of ultra-low IQ regulators might be appropriate—as they will reduce standby power for "always active" sensors or peripherals. These help to extend battery life and support the use of smaller batteries.

- Efficient regulators can significantly reduce the active power—when the wearable device is in use and measurements are being taken, or data transmissions being made.

- Integration enables sophisticated power architectures to be implemented in projects with severe spatial constraints.

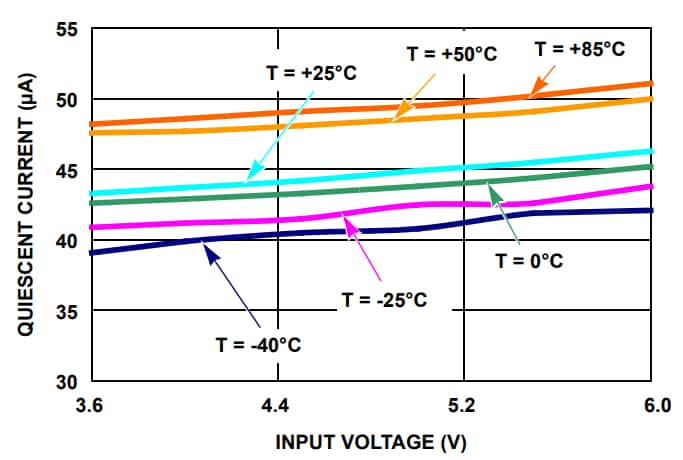

Choosing a suitable voltage regulator is a crucial factor in maximizing efficiency. It is also necessary to evaluate the current power consumption in active mode as well as in standby mode. The use of an interface with strong impedance matching can help to keep current requirements low and lengthen battery life. Cutting-edge LDO controllers such as the ISL9016 from Renesas can supply up to 150mA of current on each channel. This device is equipped with an electro-static resistance (ESR) of up to 200mΩ. The ISL9016 is also capable of operating at very low quiescent currents with a single LDO enabled (Figure 2).

Figure 2: Renesas ISL9016 LDO controller's QUIESCENT CURRENT vs INPUT VOLTAGE (VOUT1 = 3.3V, ONLY LDO1 ENABLED). (Source: Renesas)

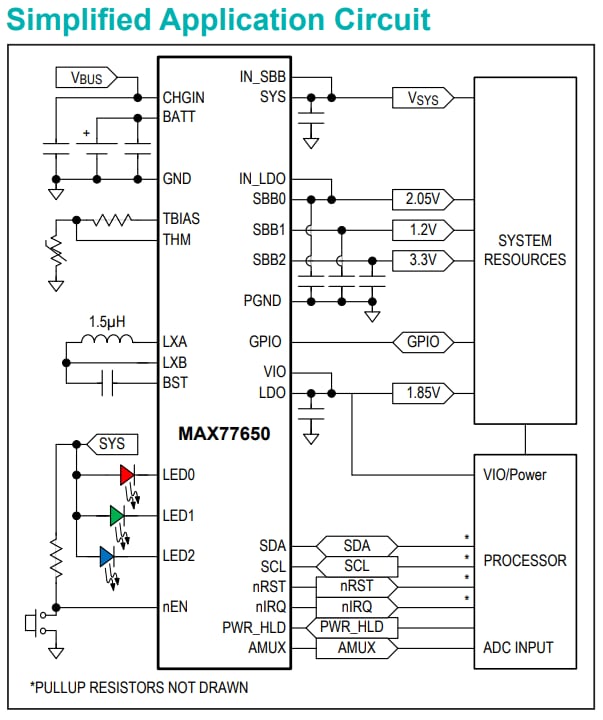

Although a switching configuration will be more efficient than using LDOs, it requires various inductors to supply different voltage rails. These increase cost and size, and so are basically impractical in a wearable's design. Rather than increasing component count and the bill of materials, as well as taking up more board real-estate, the preferred architecture for power management here will be single-inductor multiple-output (SIMO).

SIMO buck-boost regulator ICs, such as the Maxim Integrated MAX77650 (Figure 3), have a single inductor that regulates up to three output voltages over wide ranges, depending on the circuit requirements. Specifying it enables space savings, by eliminating the need for certain discrete components.

Figure 3: Maxim Integrated's MAX77650 is a highly-integrated battery charging and power supply solutions for low-power wearable applications. (Source: Maxim Integrated)

Battery Capacity versus Product Dimensions

A typical design problem is to preserve battery life in a wide variety of usage scenarios. A smartwatch often has space only for a single-cell Li-ion battery with a voltage of 3.8V and a capacity of between 130mAh and 410mAh. Li-ion is the most popular chemistry for small rechargeable batteries. The goal of battery management and the recharging system is to carefully monitor the current, voltage, and temperature during charging and operation. The main challenges are to minimize the power consumption levels of the system itself, reduce the time needed to recharge and maximize the available battery power. Texas Instruments' highly integrated BQ25100 is designed for charging single-cell Li-ion batteries and allows the use of low-cost network adapters with a non-stabilized output. This PMIC can also handle other battery chemistries, such as lithium polymers.

Although Li-ion batteries capture more of the market compared to other battery technologies, they will never be able to compete with supercapacitors in terms of power, size, and number of cycles. As wearable devices get smaller, the space inside them becomes increasingly precious. The current trend is for supercapacitors to replace rechargeable batteries, offering a new way of energy storage based on nanotechnology. Unlike batteries, supercapacitors adapt well to energy harvesting arrangements and can recharge within seconds. They can also withstand virtually unlimited charge cycles.

PrizmaCap™ from AVX are prismatic supercapacitors that can be used by themselves or in conjunction with primary or secondary batteries to help extended backup time, longer battery life, or instantaneous power pulses as needed. They are best used in applications such as wearables and in space-constrained designs requiring pulse power handling or energy storage.

Energy harvesting solutions are being studied as an auxiliary energy source for the permanent use of wearable devices, without the restrictions associated with ultra-low-power design. An interesting approach can be implemented with the generation of small electric currents by exploiting the relative movement of different layers of material—a process called triboelectric charging. The materials gain electrical charge because they create friction when moving against one another. By putting together different material layers, placed between two conductive electrodes, a few μW of power can be generated by everyday human motion—helping to recharge the battery of a wearable device and thus optimizing the power system’s operation.

Conclusion

The advent of dedicated and increasingly efficient hardware is directing the wearable market toward a large number of mobile devices. The availability of new PMICs, as well as dedicated SoCs offered by companies such as Microchip and Analog Devices, will allow the latest generation of wearables to find the right balance between energy efficiency, computing power, and compactness. When an electronic device is as small as a headset or a medical patch, the capacity of the battery is going to be limited. A broad engineering approach can help find solutions that extend battery life, saving every single μA of energy available.