Engineering Nature: Electronics Driving Seagrass Restoration

Ruggedised electronics and precision engineering accelerate ecological regeneration in the UK’s vulnerable coastal ecosystems

The finished seagrass harvester. (Source: Tandem Ventures)

Engineering is often associated with consumer convenience or industrial automation, but its role in ecological restoration presents a more complex and impactful challenge. Unlike conservation, which focuses on protecting existing ecosystems, regeneration demands active intervention to rebuild degraded habitats, combining precise and scalable engineering with environmental science.

In this sustainability project, Mouser Electronics worked with Tandem Ventures, led by engineers Sam Rogers and Edwin Towler, and Project Seagrass. Leveraging the combined expertise of engineers and ecological specialists, the team developed an innovative system to accelerate seagrass restoration. By integrating ruggedised electronics with targeted mechanical systems, the project demonstrates how industrial automation, informed by ecological insights, can make large-scale environmental regeneration faster, safer, and more efficient.

The Ecological Design Challenge

Seagrass meadows are critical carbon sinks, capable of storing carbon up to 35 times more efficiently than tropical rainforests. They account for roughly 10 percent of the ocean’s carbon despite covering only 0.2 percent of the seabed.[1] Yet historical analysis indicates that at least 44 percent of the UK’s seagrass has been lost since 1936, with long-term losses potentially reaching as high as 92 percent.[2] Beyond carbon storage, these underwater ecosystems stabilise sediments, protect coastlines, and support rich biodiversity, underpinning both fisheries and global food security.

Fortunately, regenerative conservation efforts offer a path to recovery. Organisations such as Project Seagrass are dedicated to protecting and restoring these vital meadows. Frameworks, such as those enforced by bodies like Natural Resources Wales, now provide greater protection for sensitive coastal zones, preventing the kind of reckless activity that once threatened these environments.

However, seagrass restoration relies on seed collection, which is currently a manual, diver-intensive process that is slow, expensive, and difficult to scale. The primary objective of this project was to automate this step by developing a mechanised harvester capable of collecting seeds up to 100 times faster than existing methods without disturbing sediment or the delicate rhizomes that anchor the plants.

This challenge demanded a solution that balanced precision, efficiency, and environmental sensitivity. The harvester had to operate without disturbing sediment or the delicate rhizomes that anchor the plants, while meeting environmental protection standards and selectively trimming the seed-bearing canopy.

Iterative Development of the Harvester

With the objectives clearly defined, the team at Tandem Ventures, working alongside Sam Rees from Project Seagrass, began translating them into a working prototype. The starting point was a sled architecture previously explored by Project Seagrass, which provided a foundation for a towed submersible capable of gliding just above the seabed. One key requirement was to trim the seed-bearing upper canopy without disturbing the root structures, a task that demanded precision in both motion and cutting.

Meeting this unique challenge required the harvester’s mechanical design to evolve through numerous iterations, addressing the immediate difficulties of operating in a complex marine environment. Early bench tests focused on the hydraulic transport of biomass, although standard pump configurations proved inadequate, as the shear forces generated during pumping macerated the plant material, compromising the integrity of the seed pods.

To resolve this, the team developed a vacuum-based filtration system in which water and biomass were drawn through reinforced collection vessels that served as pre-filters. Initial prototypes revealed that high-pressure differentials caused the high-density polyethylene (HDPE) containment barrels to collapse (Figure 1), prompting the team to design reinforced vessels capable of maintaining structural integrity under negative pressure while remaining vacuum-tight.

Figure 1: The collapsed HDPE barrel that prompted the redesign. (Source: Tandem Ventures)

While reducing the drag coefficient remained a key objective, field trials in shallow coastal waters introduced a constraint that quickly outweighed pure hydrodynamic optimisation. Submerged driftwood and accumulated debris created a persistent risk of fouling both the cutting assembly and the intake path. This prompted further refinement of the chassis and access design to ensure that entanglement could be cleared rapidly and safely, preserving operational continuity during extended deployment cycles.

The Electronic Anatomy of a Seagrass Harvester

While the mechanical and hydraulic systems form the backbone of the harvester, its operational success relies on the electronics supplied by Mouser Electronics, which provide control, monitoring, and data logging capabilities.

These components ensure that the harvester can operate efficiently and safely, and that the seed pods are collected without disturbing delicate seagrass structures. The electronics controlled a unique double-barrel filtration system, which allows continuous separation of biomass from water without interrupting the tow—a process critical for maintaining throughput and protecting the plants.

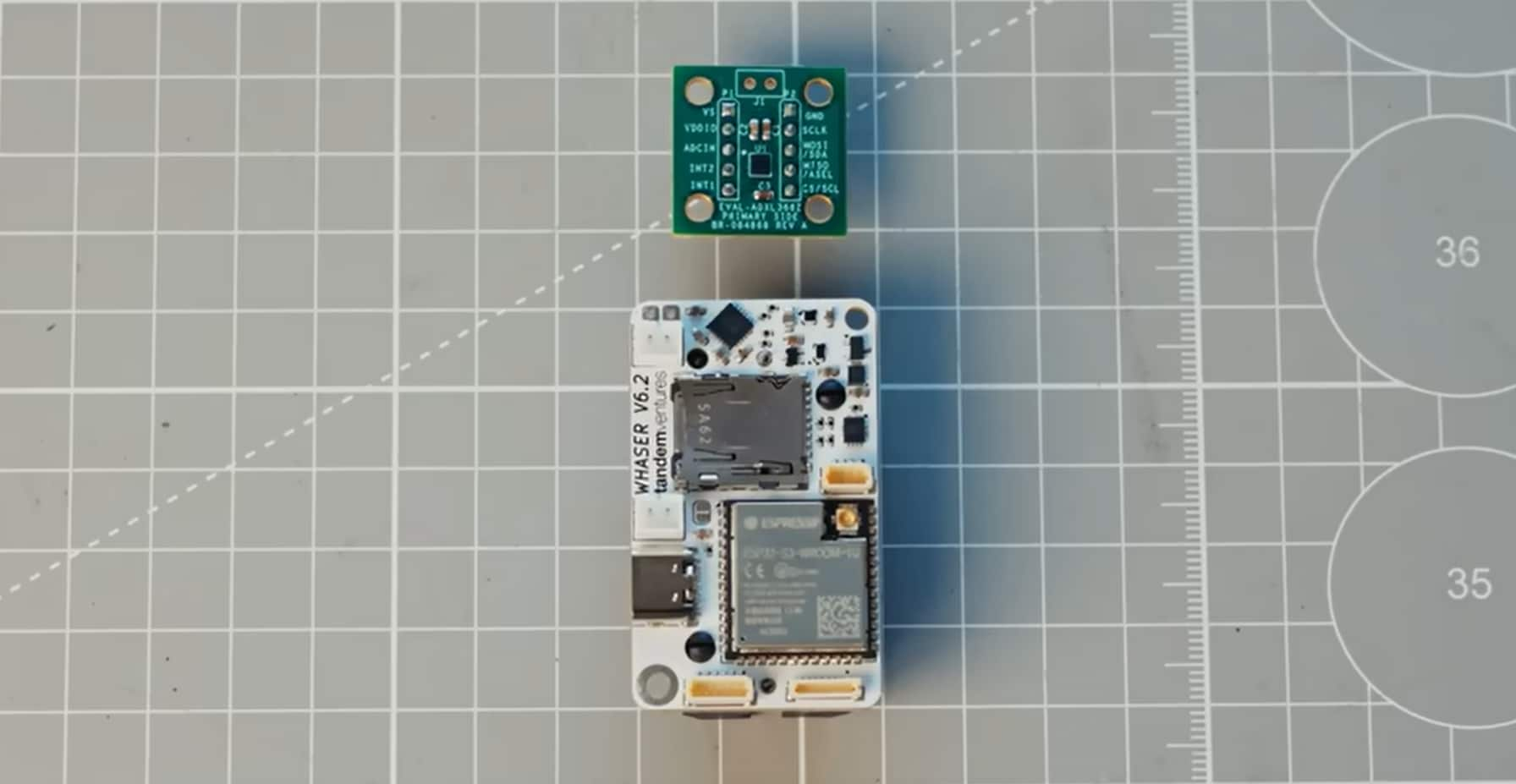

At the heart of the system is the underwater data logger (Figure 2), which acts as the harvester’s central processing and telemetry hub. It records key operational and environmental parameters, including pitch, roll, depth, water turbidity, pressure, and temperature, providing the team with insight into both the harvester’s performance and the conditions of the surrounding environment.

Figure 2: The electronic design was built upon Tandem Ventures’ WHASER technology, which was developed for a previous project with Mouser Electronics. (Source: Tandem Ventures)

The processing core is the Espressif Systems ESP32-S3-WROOM-1/1U wireless module. Built around an Xtensa dual-core 32-bit LX7 microprocessor running at up to 240MHz, it integrates 2.4GHz Wi-Fi® and Bluetooth® 5 Low Energy connectivity, 36 general-purpose input/output (GPIO) pins, and a rich set of peripherals. The module also provides hardware acceleration for signal processing and lightweight neural network tasks. While commonly used in the Internet of Things (IoT) and industrial automation, in this application, the module serves as the central controller for coordinating the mechanical subsystems, including the hydraulic cutter and double-barrel filtration system, while logging mission-critical data.

Orientation and motion are tracked by inertial measurement units (IMUs), including the Analog Devices EVAL-ADXL362 evaluation board and the STMicroelectronics LSM6DSO 6-axis IMU. These components deliver high-resolution measurements of pitch, roll, and vibration, allowing operators to confirm that the cutter maintains the correct height and angle above the seabed, avoiding disturbance to sediment and rhizomes.

Within the harvester, robust interconnects from JST and Hirose Electronics ensure reliable operation in high-pressure, high-moisture conditions. The system is housed within a pressure-rated enclosure featuring a perforated sensor bay, which allows the harvester to collect environmental data while protecting sensitive components from water ingress.

Together, these low-power, off-the-shelf components provide precise control over the harvester’s cutting and filtration systems, enabling high-throughput seed collection while preserving delicate habitats. The project demonstrates how thoughtful engineering and compact electronics can scale ecological restoration efforts, supporting faster, safer, and more efficient recovery of seagrass meadows while safeguarding the environment.

Validation and Field Impact

After final assembly and thorough safety approvals, the harvester was transported to Porthdinllaen Bay, North Wales, for testing in a sensitive seagrass meadow. The primary objective of this field trial was to validate the fully integrated system, ensuring the coordination of the hydraulic cutter, towable chassis, and double-barrel filtration system while collecting seed pods without disturbing sediment or rhizomes.

Testing occurred outside the peak seed collection season, meaning only a very small number of seed pods were available—enough to validate the system, but not a significant harvest. Even this limited recovery provided critical empirical confirmation that the design functioned as intended (Figure 3). During testing, the reinforced filtration barrels withstood operational pressures, and the hydraulic cutter maintained consistent depth and angle thanks to real-time feedback from the IMUs.

Figure 3: An image from inside the harvester during field testing (Source: Tandem Ventures)

Data recorded by the underwater logger confirmed that both the harvester’s movement and environmental conditions were within safe parameters, verifying that ecological safeguards were upheld during seed collection. Following these successful trials, the harvester was delivered to Project Seagrass headquarters, marking a milestone in its development and providing a working system with scope for refinement, offering a foundation for more efficient and scalable seagrass restoration in the future.

Conclusion

The seagrass harvester demonstrates how targeted engineering and electronics innovation can directly support ecosystem regeneration. By integrating innovative off-the-shelf components with precision mechanical systems, engineers can scale conservation efforts that were previously slow and labour-intensive.

Projects like this highlight the potential for collaboration across product design, environmental conservation, and electronics sectors to create solutions that are both effective and environmentally sensitive. More broadly, the initiative underscores the role the electronics industry can play in enabling measurable ecological impact, demonstrating that the intelligent use of technology and out-of-the-box thinking can accelerate the restoration and protection of critical habitats worldwide.

Sources

[1]https://www.unep.org/news-and-stories/story/seagrass-secret-weapon-fight-against-global-heating

[2]https://doi.org/10.3389/fpls.2021.629962