Powering Electric Motor Drives

Image Source: nordroden/stock.adobe.com

By Alistair Winning for Mouser Electronics

Published December 15, 2025

Some of the most popular motor types used today would not be viable without control methods based on powerful microcontrollers processing complex algorithms; for example, a permanent magnet synchronous motor (PMSM) and brushless DC (BLDC) motor both require extensive mathematical calculations to operate effectively. Microcontrollers are generally at their best when making intricate calculations, not delivering precise amounts of power. Although some microcontrollers integrate circuitry that can provide the necessary power, a dedicated power system is often required.

In this article, we will examine the architectures and components that go into powering electric motors.

Architecture

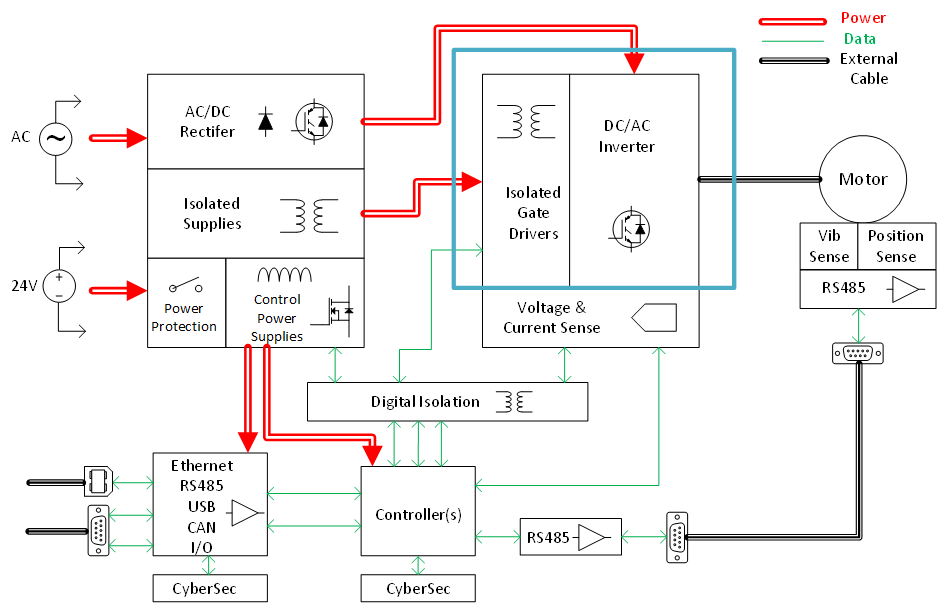

The most widely used method of delivering power to the stator coils in three-phase AC and BLDC motor control designs is using an inverter (Figure 1). In most three-phase AC motor designs, the supply voltage is initially converted to DC, and then that DC signal is converted to the desired AC frequency and magnitude using pulse width modulation (PWM).

Figure 1: The inverter’s place in the overall motor control schematic. (Source: Analog Devices)

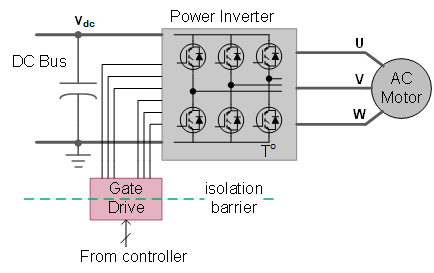

Various types of inverters can be used depending on the topology and the number of phases in the motor design. Still, the most popular way of delivering the PWM signal is through a three-phase, two-level configuration (Figure 2). In this case, the inverter bridge consists of six transistors, each with a flyback diode across the transistor to protect it from sudden voltage spikes that occur when the supply current is reduced quickly from an inductive load, such as a motor. The six transistors are controlled independently by six gate drivers and are fully turned on or fully turned off at a high frequency. They act as quasi-ideal switches to modulate the voltage to the stator electromagnets, recreating the PWM signal to control the motor’s speed. BLDC motors are controlled in a similar way, but no initial rectification is required, as the input voltage is already DC.

Figure 2: Inverter stage driving a three-phase motor. (Source: Analog Devices)

Power Components

MOSFETs and IGBTs have traditionally been used to act as switches in inverter designs to deliver power. MOSFETs can potentially switch at frequencies up to 100kHz, but are more often used at speeds in the tens of kHz. They use a manufacturing process similar to that of the ICs that control them, meaning that a single-chip solution is possible for some lower-power applications. Other advantages of MOSFETs include high input impedance, low on-resistance, low gate power consumption, easy driving, and a wider safe operating area. These traits make MOSFETs ideal for applications requiring an energy-efficient solution for low current densities. However, as the voltage increases, the junction temperature also rises, and the reverse recovery performance of their internal diode deteriorates, causing increased heat and switching losses.

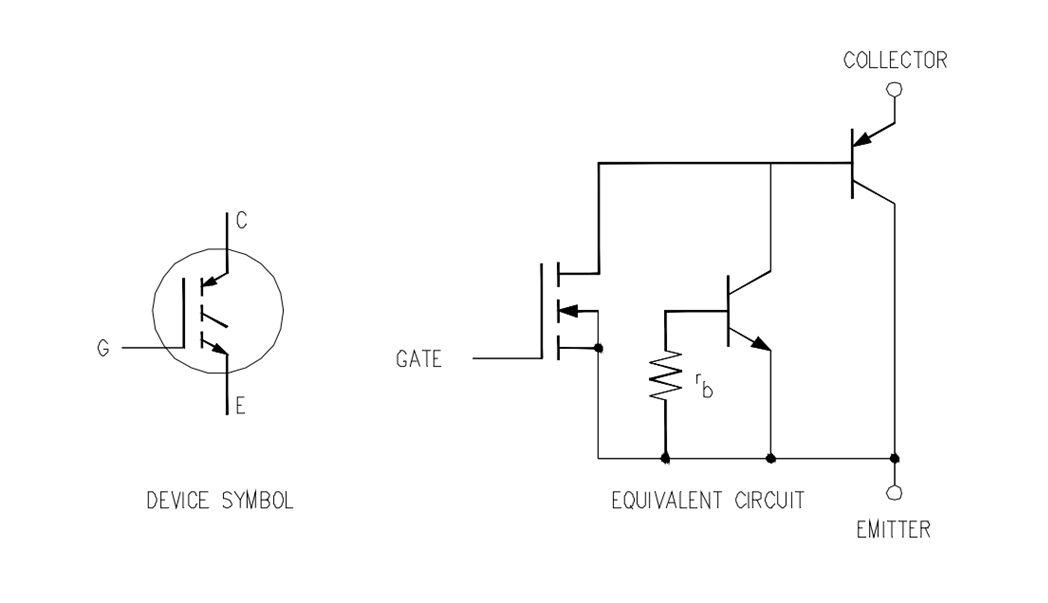

At those higher voltage and current levels, IGBTs are usually the preferred choice of switching devices. IGBTs have a similar structure to MOSFETs, but an extra P+ layer is added at the collector, making it act like a MOSFET driving a PNP transistor (Figure 3). They are easy to drive using a low-power signal and operate at lower frequencies of around 20kHz. However, IGBTs’ designs prohibit them from being manufactured on a typical MOS IC process, meaning that they do not have an integrated internal reverse recovery diode like a MOSFET. For motor control purposes, such a diode must be used, either externally on the PCB or packaged as a separate die along with the IGBT. External recovery diodes present both advantages and disadvantages: They can be tailored to the specific application, but doing so will add cost to the design and require extra PCB space.

Figure 3: IGBT symbol and equivalent circuit. The collector terminal is the emitter of a PNP transistor. (Source: Infineon)

Key Parameters

For both MOSFETs and IGBTs, current handling and peak-voltage ratings are the primary traits needed to meet the requirements of the motor’s load. After those specifications, the two devices have secondary and tertiary requirements.

The most important secondary parameters of MOSFETs are drain-source on-resistance (RDS(ON)) and gate capacitance. Lower on-resistance reduces resistive losses and lowers the voltage drop when the device conducts, directly resulting in greater efficiency. However, it is not as straightforward as it seems. The gate capacitance is a factor in how quickly conductance can be turned off and on, which can be calculated from the equation I = C dV/dt. Along with the switching frequency, it also contributes to losses at the gate. The higher the switching frequency, the greater the losses and the lower the efficiency. A MOSFET designed to have a lower RDS(ON) will usually have a larger gate area, which leads to a higher gate capacitance. So, a trade-off can be achieved between the RDS(ON) and gate capacitance to get the best performance and lowest losses. Manufacturers almost always give an idea of the overall value as a figure-of-merit (FOM) in the datasheet using the equation FOM = RDS(ON) × gate charge (QG).

For IGBTs, the on-state voltage drop is a critical specification to consider. This drop includes both the diode drop across the P-N junction and the voltage drop across the driving MOSFET. Contrary to a pure power MOSFET, the on-state voltage drop of an IGBT does not fall below the threshold of a diode.

Selecting the right component is not just a matter of choosing the right figures from a datasheet because the parameters change during operation. Both the RDS(ON) of the MOSFET and the on-state voltage drop of the IGBT are affected by both temperature and current, and both types of devices are susceptible to heating during operation. The MOSFET’s voltage drop is proportional to the current, and its RDS(ON) increases with temperature. The voltage drop in an IGBT is similar to that of a diode, increasing with the log of the current and remaining relatively constant with temperature.

The Wide Bandgap Revolution

Until recently, silicon MOSFETs and IGBTs were the components of choice to power electric motors. Many applications remain perfectly acceptable options, but now further choices are available due to the commercialization of wide bandgap technologies. Over the last decade, gallium nitride (GaN) and silicon carbide (SiC) semiconductors have come onto the market, offering traits better than silicon transistors in almost all cases.

The bandgap is the energy required for electrons and holes to transition from the valence band to the conduction band. While silicon has a bandgap of 1.12eV, SiC and GaN have bandgaps of 3.26eV and 3.39eV, respectively. The breakdown fields of the three materials tell a similar story. SiC is 3.5MV/cm, GaN is 3.3MV/cm, and silicon is 0.3MV/cm. These figures mean that GaN and SiC are over ten times more capable of maintaining higher voltages. In practical terms, the two wide bandgap materials can switch faster and handle higher voltages for longer, making them more efficient. They can also withstand higher operating temperatures than silicon—around 600°C for SiC and 300°C for GaN, compared to only 200°C for silicon devices. Those benefits alone mean that wide bandgap designs can provide smaller and lighter solutions, better performance, and easier thermal management.

Although the bandgap figures look similar for GaN and SiC, their electron mobility figures are very different and play a large part in dictating how the materials are used for power-handling applications. Electron mobility measures how fast an electron can travel through a conductor or semiconductor material when pulled by an electrical field. GaN is the fastest with an electron mobility of 2,000cm2/Vs, followed by silicon at 1,400cm2/Vs, and then SiC at 650cm2/Vs.

Those better specifications mean that GaN can switch rapidly—ten times faster than silicon MOSFETs. The very low gate capacitance of GaN designs also leads to lower switching losses. A great example of how GaN transistors can transform power designs is seen in USB chargers for mobile phones. These chargers have decreased in size, even as their power-handling capabilities have grown from around 11W to 70W. As such, GaN provides an ideal solution for motor applications up to 650V and 20kW that need the highest efficiency possible.

On the other hand, SiC switches a lot slower than GaN while still being faster than silicon solutions. The material offers additional power delivery benefits, such as high voltage and current handling, high thermal conductivity, and robustness. The higher switching frequencies of SiC make it preferable for designs that require high efficiency and accuracy up to around 1,200V and 200kW.

Of course, there are trade-offs required to get that better performance. Wide bandgap semiconductors are much harder to drive than MOSFETs and IGBTs, leading to increased design time and complexity. Additionally, one of the most significant advantages of using wide bandgap materials is that the faster switching allows smaller filter components to be used. However, motor applications don’t use filters extensively, as the motor windings can be used to smooth the PWM signal. Even the moderate switching speeds provided by MOSFETs and IGBTs offer almost perfect waveforms. SiC and GaN transistors can also suffer reverse recovery losses in operation.

Based on initial cost, IGBTs and MOSFETs are less expensive than SiC and GaN transistors, which means they may be a better option for many cost-sensitive applications. However, although SiC and GaN transistors are more expensive than their silicon counterparts, their higher efficiency in the field may make them the less expensive solution over the entire application lifecycle.

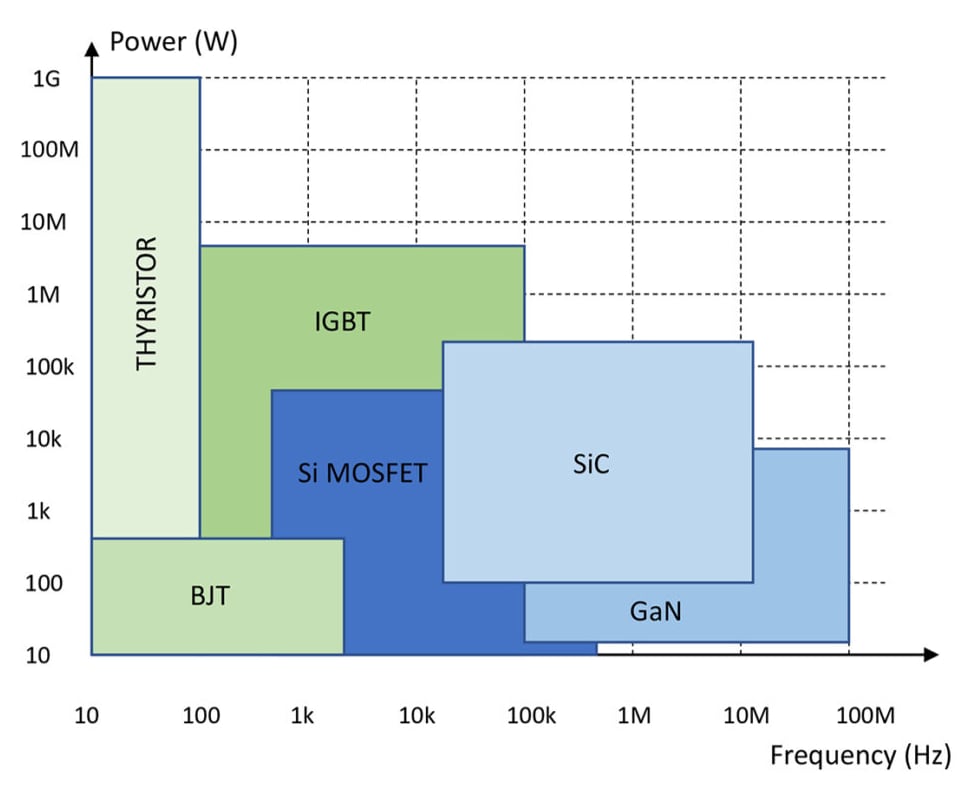

All the types of transistors we have described are perfectly acceptable choices, depending on the applications’ needs. In fact, as shown in Figure 4, there are significant overlaps at around the 100kHz/10kW level, and all four transistor types may be viable choices. Of course, as GaN and SiC transistor technology matures, future generations of the devices will likely improve in performance and lower in cost. That’s not to say that IGBTs and MOSFETs will remain as they are now. For example, recently introduced trench IGBTs offer improved performance, reduced size, and better thermal performance.

Figure 4: The approximate application areas of modern power semiconductors. (Source: Qorvo)

Conclusion

Electric motor drives rely on more than just advanced control algorithms. They demand efficient, robust power delivery systems. Traditional silicon-based MOSFETs and IGBTs have served this role well, offering proven performance across a wide range of applications. However, the emergence of wide bandgap technologies, such as GaN and SiC, is reshaping the landscape, enabling higher switching speeds, improved thermal management, and greater overall efficiency. While these newer devices introduce design complexity and higher upfront costs, their long-term benefits in size, performance, and lifecycle efficiency make them increasingly appealing for modern motor applications. Ultimately, selecting the right solution depends on balancing voltage, current, thermal, and cost considerations.

This article was generated with assistance from Copilot for Microsoft 365.