Choosing the Right Inverter for Residential Solar Systems

(Source: ArgitopIA/stock.adobe.com; generated with AI)

The worldwide residential solar market is poised for strong growth after a tenuous 2024. According to McKinsey & Company, the boom observed from 2020 to 2023, fueled in part by government incentives, was not sustainable.[1] As those incentives were pared back and interest rates rose, the industry faced headwinds. But rising electricity rates and falling residential solar equipment costs are keeping solar technology competitive, even without the incentives, and McKinsey forecasts that residential solar’s cumulative installed capacity will more than double by the end of the decade.

To meet the needs of this growing industry, manufacturers must offer optimized solutions for every customer. Residential solar installations present particular challenges, with an emphasis on compact, high-power-density, and low-cost systems that operate safely and fit unobtrusively into an environment not necessarily designed to accommodate solar equipment. To best serve the residential market, manufacturers and installers will need expertise in solar-inverter topologies and detailed knowledge of the electronic components that make up a residential solar system. In this blog, we detail key solar topologies and investigate some of the reliable, fast-switching electronic components crucial to developing effective residential solar systems.

The String Inverter

When choosing an inverter for solar system designs, key topology options include the string inverter and the microinverter. A residential string inverter takes the DC output of several photovoltaic (PV) panels in series and inverts it to an AC power level that matches the frequency and voltage level of the utility grid with which it will interface. Like most PV inverters, a string inverter typically incorporates maximum power point tracking (MPPT) to ensure extraction of the maximum possible power from PV panels in accordance with the panels’ varying illumination levels. One drawback to the string inverter is that if one of many panels connected to it experiences partial shade, that panel—the “weakest link”—will limit the total available output power.

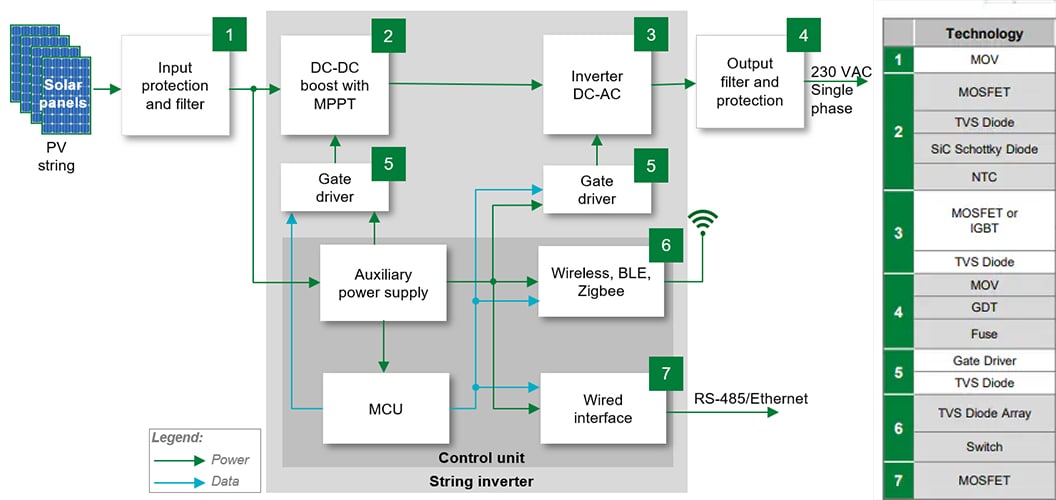

In a typical string inverter (Figure 1), a group of panels connects to input protection and filtering circuitry, which incorporates devices such as metal-oxide varistors (MOVs) that provide high energy absorption capability and meet third-party safety standards. From the filter stage, DC power flows to a DC-DC boost converter with an MPPT, which makes use of metal-oxide semiconductor field-effect transistors (MOSFETs). The DC-DC stage connects to a DC-AC inverter, which incorporates MOSFETs or insulated-gate bipolar transistors (IGBT) to generate an AC power level that matches the utility grid, such as 230V at 50Hz (common in Europe and many other regions) or 120V at 60Hz (common in North America). Finally, an output filter and protection stage makes use of MOVs, fuses, and other protection devices to generate a safe, smooth output voltage.

Figure 1: Diagram of a string inverter connecting to multiple solar panels. (Source: Littelfuse)

The Microinverter

In contrast, the microinverter connects to a single solar panel, and each individual microinverter’s MPPT will extract the maximum power possible for a particular panel’s level of illumination. Consequently, a partially illuminated panel does not limit the power level available from other, fully illuminated panels, eliminating the string inverter’s “weakest link” problem.

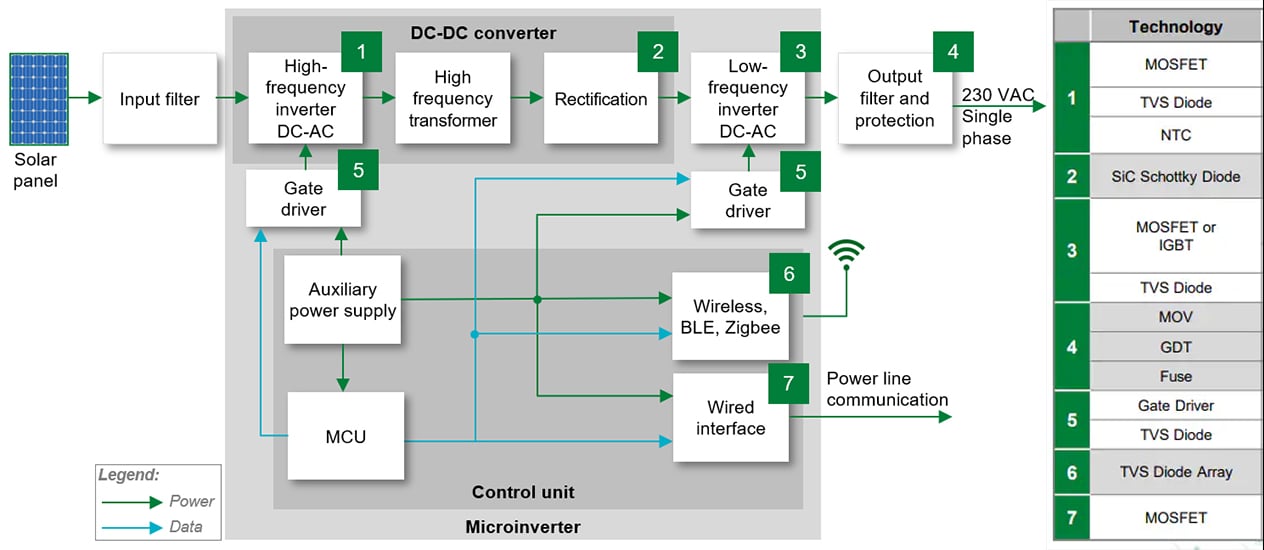

As shown in the implementation in Figure 2, a single solar panel connects to a microinverter’s input filter, which in turn connects to a high-frequency DC-AC inverter that incorporates MOSFETs. That inverter’s output is routed to a high-frequency transformer. This transformer provides the galvanic isolation between the panel and the grid connection that is often required by relevant electrical codes for grid-connected renewable energy systems, such as UL 1741 or IEC 62109. Because of the high frequency, the transformer can be much smaller than it would be if it were operating at the 50Hz or 60Hz grid frequency. The transformer’s output is rectified and then goes to a low-frequency DC-AC inverter, which employs MOSFETs or IGBTs to develop the 230V, single-phase 50Hz or 60Hz voltage that gets smoothed in the output filter and protection stage.

Figure 2: Diagram of a microinverter connected to a single solar panel. (Source: Littelfuse)

Other circuit blocks common to both the string inverter and microinverter include gate drivers that control the power switches used in the DC-DC converters and DC-AC inverters. Effective gate drivers offer fast rise and fall times, high immunity to latch-up, and fast thermal response in compact packages. The inverters also incorporate auxiliary power supply, which derives a regulated DC voltage from the panel input voltage to power the inverter circuitry, including a microcontroller unit (MCU), gate drivers for the DC-DC and DC-AC power components, and wired and wireless communications interfaces, which report operating conditions like panel voltage, AC voltage, and temperature to other connected equipment.

Littelfuse Residential Solar Solutions

Navigating the specific power management requirements of residential solar environments demands a wide range of component options for different energy needs. Littelfuse offers a broad portfolio of circuit protection, MOSFETs, and gate drivers for residential solar systems. Their residential solar solutions feature a variety of components for use throughout inverter designs, ranging from cartridge fuses to silicon (Si) and silicon-carbide (SiC) MOSFETs and MOSFET modules. Discrete MOSFETs provide maximum design flexibility, while Littelfuse’s MOSFET modules, which incorporate fast recovery diodes, enable compact, high-power-density designs.

For a string inverter’s DC-DC boost phase with MPPT, Littelfuse offers MOSFETs with ultra-low on-resistances (RDS) and high current-handling capability. These devices are easy to mount and save space as a result. For the microinverter rectification stage, Littelfuse’s silicon Schottky diodes provide very low forward voltage drops. These devices ensure low current leakage and are available in a common-cathode configuration with single-screw mounting.

For the DC-AC stages in both string inverters and microinverters, Littelfuse offers MOSFETs and IGBTs that can handle high surge currents with reduced thermal resistance and fast switching speeds to minimize losses. And for the inverters’ input and output filter stages, they provide MOVs that deliver high energy-absorption capability and reduce qualification times by complying with third-party safety standards. These residential solar solutions feature a variety of MOVs with wide ranges of voltage, current, and energy ratings. In addition, Littelfuse’s range of cartridge fuses are suited for output stages. Available in a variety of package sizes and ampere ratings, these fuses are available with fast-acting, medium-acting, and time-delay characteristics to meet specific application requirements.

Littelfuse also offers components that can be used throughout string inverters and microinverters, including transient-voltage-suppression (TVS) diode arrays that protect against voltage surges and negative-temperature-coefficient (NTC) sensors that can detect overtemperature conditions.

Conclusion

The burgeoning residential solar energy market presents significant opportunities for inverter manufacturers and system installers. Players across the industry will gain a competitive advantage by choosing the optimal topology for each residential end customer’s specific application and by implementing the required equipment using high-performance, reliable, and compact components ranging from cartridge fuses to power MOSFET modules.

[1]https://www.mckinsey.com/industries/electric-power-and-natural-gas/our-insights/residential-solar-down-not-out

Author

Rick Nelson is a technical journalist who has served as executive editor of Test & Measurement World, chief editor of EDN, and executive editor of EE-Evaluation Engineering. He has also contributed to publications including Vision Systems Design and Electronic Design, and he has participated in many live panel discussions and webcasts. Rick has also held systems-engineering and product-development positions at General Electric and Litton Industries. He received his B.S.E.E. degree from The Pennsylvania State University.

Rick Nelson is a technical journalist who has served as executive editor of Test & Measurement World, chief editor of EDN, and executive editor of EE-Evaluation Engineering. He has also contributed to publications including Vision Systems Design and Electronic Design, and he has participated in many live panel discussions and webcasts. Rick has also held systems-engineering and product-development positions at General Electric and Litton Industries. He received his B.S.E.E. degree from The Pennsylvania State University.